German-based company known for its orange industrial robots and automation solutions Kuka has founded a digital business segment. Known as Kuka Digital. Its aim is the end-to-end digitalization of a wide range of machines and systems in production, from the first 3D simulation to connectivity and data analysis through to the use of artificial intelligence.

Software is playing an increasingly important role in mechanical engineering. What used to be mostly solved mechanically is now done by electronics and the associated software. “With Kuka Digital, we are expanding our offering in order to position ourselves broadly for a market with strong growth potential. Our customers need products, solutions and consulting approaches to digitalize faster, more efficiently and more easily,“ said Quirin Goerz, Chief Information Officer and CEO of the newly founded digital segment. i

Specifically, the digital segment is focusing on a software and digital portfolio that is not limited to Kuka robots. Regardless of machine type and manufacturer, customers should be able to use software solutions for their production machines and thus digitalize their production halls from end to end. This involves interfaces, data standards, cloud integration and consulting services. In line with an ecosystem approach, the company also relies on a network of competent partners.

The new digital segment

With Device Insight and Visual Components, the company says it already has strong, independent brands in the areas of Internet of Things (IoT), data analytics and simulation software within the Group.

Device Insight helps companies to digitalize their production and business processes based on IoT, data analytics and artificial intelligence, making them more transparent and efficient. Visual Components develops 3D simulation software as well as offline programming for manufacturing. Manufacturing companies use the software to plan production layouts, simulate processes in advance or program machines offline beforehand.

Cloud platform for industrial software

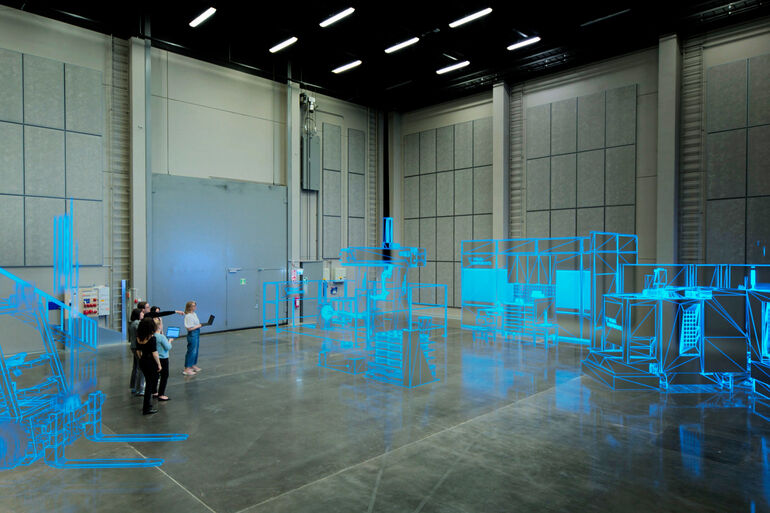

Planning, implementing and operating a production facility is a complex process. A wide variety of machines need to be harmonized with one another. With regard to the associated software, this currently still means working with isolated solutions and a high level of manual effort. This is why, in addition to Device Insight and Visual Components, mosaixx will be augmenting KUKA Digital‘s portfolio this year. This is an open, collaborative cloud platform for Industrial Software-as-a-Service (SaaS) and forms the basis for the digital twin with a combination of tools (software), data management, cloud computing and process understanding.

System integrators and other engineering customers have access to a wide range of software solutions for ECAD and MCAD programs, simulation, offline programming as well as virtual commissioning. The solution enables engineers to efficiently structure and securely link their workflows within a project in a shared and location-independent working environment with processes, workflows and cloud storage.