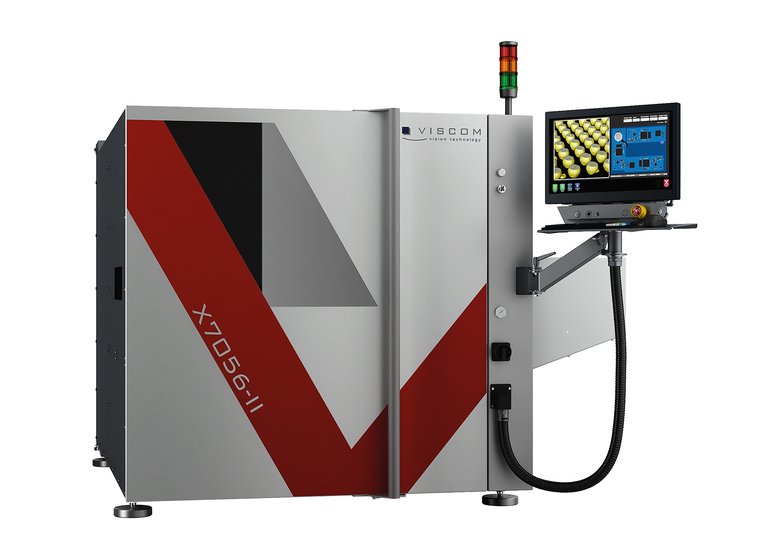

Viscom AG has received the productronica innovation award in the category Inspection & Quality, because of the automatic 3D X-ray inspection system, the X7056-II.

It is the next generation of the X7056RS model. The board handling solution xFastFlow makes this system ideal for use in production lines that require high throughput despite extensive inspection of hidden solder joints. Up to three PCBs can be processed simultaneously in the system. It is now possible to achieve handling times (component infeed and outfeed) of even less than four seconds. Due to the time saved, 3D inspections, which used to be done selectively, can be expanded to cover far more than just individual components.

For an optimum configuration, high-performance flat panel detectors (FPD) are available in different sizes, and e.g., with a xy-table for planar CT. Inspection depth and throughput are flexibly adaptable to meet individual requirements. 2D, 2.5D, and 3D inspection can be combined to run in succession for ultimate coverage. Images are acquired from as many different angles as necessary in a single pass and three-dimensional digital reconstructions of inspected objects become highly accurate.

With the company’s own development of planar CT software algorithms, the system offers 3D AXI image reconstruction procedures that reduce interfering structures more effectively than ever before. Even from double-sided printed circuit boards with a very complex overlap of components on both sides, easy-to-analyze layers can be mathematically extracted. The x-ray inspection system automatically resolves any covered areas to clearly reveal important defect features and allow exact evaluations.

As with the predecessor system, an optional combination with automatic optical inspection (3D AOI) in one machine housing is a fixed component of the development. The X7056-II can offer the high optical inspection depth of the newest AOI solutions, and this with comparable throughput. Investment spending is reduced as AOI and AXI are optimized effectively within just one system. By taking advantage of the third dimension, users have the benefit of a view of all components and solder joints without shadows.

Furthermore, customers can now choose between the company’s vVision and EasyPro (SI) inspection software, which provide intuitive operation as well as quick generation of multiple inspection programs. Effective networking and up-to-date statistical process control are also important features.