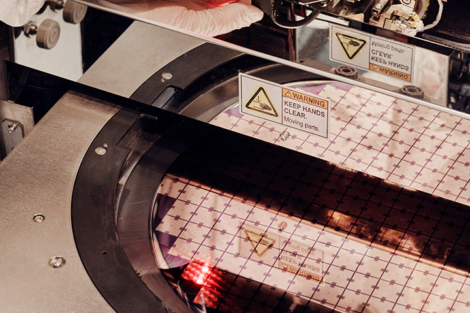

The flip-chip bonder AFM-15 offers significantly faster bonding at 1.1s per chip (including bonding time), compared to the nearest comparable method of gold-wire bonding. It is targeted to production of LEDs, RF-components and CSPs or any other components, which profit from incorporating the benefits of this process technology, providing all in one run for mounting and bonding of high-precision parts.

The bonder uses the gold-to-gold ultrasonic-interconnecting method, allowing for considerable reduction in weight and size of the package. The AFM-15 also supports lead-free manufacturing. This machine addresses the industry demand for further miniaturization and better electric features for products, such as short ways for signals and better transfers of frequencies, alongside with enhanced temperature resistance.

EPP EUROPE 438

Share: