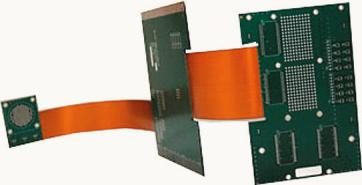

“Advanced Flexible Circuits Inc. of the USA” (AFC) is a rigid-flex and flexible circuit specialist. Flexible printed circuits were designed as a space and weight saving replacement for traditional cabling and connectors in point-to-point interconnections. There are primarily four types of flexible circuit: single-sided, double-sided, multilayer and rigid-flex. The lack of mechanical connectors and elimination of manual wiring in an integrated circuit reduce wiring errors and greatly increase signal quality and impedance, while the circuit fits into spaces that no standard cable and connector harness would.

Single sided are normally specified for dynamic flexing applications such as printers, disk drives and internal laptop to screen wiring. Such AFC products have reliably undergone 500 million flex cycles without failure. Double sided and multilayer are used in relatively static applications where increased circuit density is required. Rigid-flex types combine elements of flexible circuitry with rigid boards, almost entirely negating the use of mechanical connectors, and are great for motor vehicle dashboard cluster wiring, hand-held communication devices, etc. – especially those requiring strain free bonding of SMT devices. These hybrid hard board/flex circuits can have up to 20 layers of flex interconnects, sandwiched between rigid outer layers.

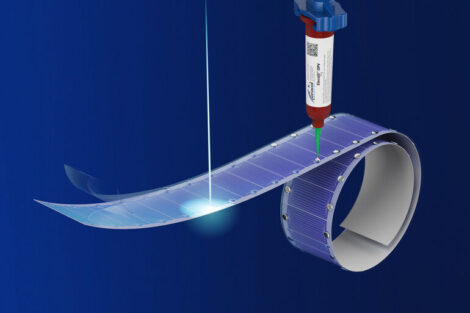

Vibrations and shocks that would crack rigid PCBs have little or no effect on flexi circuits. The base material on which the signal circuits are plated will dictate the temperature range for a given integrated circuit. To ensure higher yields and customer satisfaction, AFC design engineers, quality, and manufacturing teams work with the client. The goal is to assess the thermal, mechanical and environmental situation so as to offer the optimum materials, construction, solderability and cost for a given task.

EPP EUROPE 402

Share: