Precise cutting and removing of thin foils is becoming an omnipresent task in today’s microelectronic production industry. With the new laser sublimation system RSL 5000, Ricmar is supplying a state-of-the-art tool in terms of stability, accuracy, user friendliness and UPH for meeting modern industries demands.

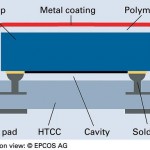

In modern SAW technology, SMD chips are for example encapsulated in thin polymer foil. To guarantee hermetical sealing, the foil needs to bond with the chip substrate, which is usually a ceramic substrate. The foil is being removed by means of laser sublimation around the chip. This has the advantage of sealing the package while simultaneously removing undesired foil within dicing lanes.

Highly critical during this process is the heat transfer to the sensitive chip components itself. Therefore the RSL 5000 is using a pulsed CO2 laser to minimize heat transfer. Foil thicknesses cut at this application, range between 10 μm and 100 μm with cutting widths of 300 μm at cutting speeds of up to 1000 mm/s. Achieved accuracies for this process are ± 10 μm (3 s) on a 100 by 100 mm area.

By choosing the appropriate laser source and optics, this process can be adapted to different kind of foil materials and cutting widths. A true multi axis motion control system enables the machine to cut complex geometries with ease. Due to its modular design, the RSL 5000 can be tailored to customer needs in terms of cutting accuracy, and cutting area.

The user-friendly GUI allows for an easy and foolproof operation and programming which saves valuable time during product changeovers. According to different user levels with corresponding access rights, access to critical process data can be limited to only skilled operators. Furthermore, the software can easily be extended to meet any customers needs, thereby offering the greatest possible flexibility. One of the company’s strengths is its fast and highly reliable image recognition software, which is also incorporated into the RSL 5000. Recognition of any given optical labelling standard as well as alignment marker is carried out at state-of-the-art precision in the twinkling of an eye. Using equipment such as the RSL 5000, cutting and removing of thin foils becomes an economical, repeatable and reliable process.

The process itself is readily adaptable to many kinds of similar cutting and stripping processes. Ricmar provides turnkey, fully automated systems for the semiconductor, microelectronics, photovoltaic and automotive industries.

EPP Europe 449

zusammenfassung

Das präzise Schneiden und Entfernen von dünner Folie ist eine allgegenwärtige Aufgabe in der Produktion von Mikroelektronik. SMD-Chips werden in dünner Polymerfolie eingekapselt. Ein neues Laser-Sublimationssystem ermöglicht das präzise Schneiden und Strippen von dünner Polymerfolie.

Découper et retirer les feuilles minces est l’un des travaux les plus courants de la production des composants microélectroniques. Les puces SMD sont enveloppées dans une mince feuille polymère. Un nouveau système de sublimation laser permet de découper et de retirer avec précision la mince feuille polymère.

Il taglio e la rimozione con precisione di pellicole sottili è una delle normali attività nella produzione microelettronica. I chip SMD vengono incapsulati in pellicola polimera. Un nuovo sistema di sublimazione laser consente di tagliare e rimuovere con precisione la sottile pellicola polimera.

Share: