Pickering Electronics was formed in January 1968, with the aim to design and manu- facture high quality reed relays, intended principally for use in Instrumentation and Test equipment. Today, the company’s Single-in-Line (SIL) range is by far the most developed in the relay industry with relays 25% the size of many of their competitors. The small SIL relays are sold in high volumes to large ATE companies throughout the world. The reed relays feature the highest quality instrumentation grade reed switches making them suitable for the most demanding applications. Internal mu-metal magnetic screens allow very high packing density.

Graham Dale, Pickering Electronics, Clacton-on-Sea (UK)

Pickering relays have many advantages over the more usual ‚Hard Moulded‘ construction. They are constructed using SoftCenter-technology which greatly reduces stress on the delicate glass reed switch capsule for maximum life and performance. Mu-metal magnetic screening allows high packing density without the risk of problems due to magnetic interaction between relays.

No problems anymore in high density applications

Reed Relays remain an attractive solution for switching applications. Having a metallic path, they do not suffer from the problems of relatively high off-state leakage current and non-linearity associated with solid state relays. Often though, they are considered a mundane component and little thought is given to them by the design Engineer which can lead to problems. Several series of single-in-line reed relays are available from Pickering Electronics that may be stacked on a 0.15 inches pitch. The high packing densities achievable with these very small relays can be very useful, particularly where large numbers are used, for example, in automatic test equipment and data acquisition. These relays all feature mu-metal magnetic screening to avoid magnetic interaction problems.

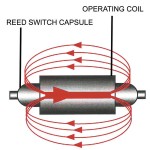

A reed relay in its most basic form consists of a pair of ferro-magnetic switch contacts enclosed in a sealed glass envelope. Around this is wound a coil of wire which acts as an electro-magnet to close this switch when an energising voltage is applied. This magnetic field, however, completely surrounds the device and affects any other relays that may be close by.

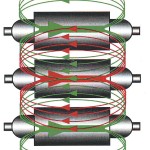

An external magnetic field acting upon a reed relay will, according to polarity, either add or subtract from the devices own magnetic field, resulting in a change in the coil voltage required to operate the device. Where many relays are packed very densely, for example, in an ATE switching matrix, it is possible for this interaction to prevent a relay from operating. This can best be understood with a little arithmetic and a simple example.

The industry standard specification for the coil voltage by which a reed relay must operate is 75 per cent of its nominal value, for a 5 volt device this would be equal to 3.75 volts at 25 degrees Centigrade. Let us imagine three relays stacked side by side with the outer two energised. We now wish to turn on the middle one. This device at 25 degrees Centigrade, as an example, may have an operating voltage of 3.5 volts, still 0.25 volts lower than its ‘must operate’ limit.

Importance of magnetic screening

The temperature inside this equipment may be somewhat higher than this, let us suppose 50 degrees Centigrade. We know that the co-efficient of resistance of the copper coil wire is 0.4 per cent per degree Centigrade. The voltage required to generate the magnetic field to operate the switch will need to be increased at this same rate to maintain the necessary coil current, so the operating voltage is now 3.85 volts. The magnetic fields from the two outside relays acting on the centre one will tend to increase further the voltage required to operate the switch. An increase of a further 30 to 40 percent is perhaps surprisingly, a realistic one for unscreened relays on 0.15 inches pitch. With a 30 percent increase, the figure now calculates to a little over 5 volts.

But we only have a 5 volt supply and we have not as yet allowed for a drop across our driver, the relay will not turn on.

This is why magnetic screening is so important. The company believes that the only correct solution to this problem is mu-metal magnetic screening, mu-metal because of both its high permeability and low magnetic remanence. All single-in-line relays of the company have this feature. Magnetic screening is absolutely essential for relays mounted on a close pitch.

Zusammenfassung

Reed Relais eignen sich als attraktive Lösung bei Schaltungsanwendungen. Der Artikel veranschaulicht die magnetische Wechselwirkung sowie die Temperatureffekte, um die Bedeutung einer magnetischen Abschirmung aufzuzeigen.

Les Reed Relais sont adaptés en qualité de solutions attractive pour les applications de commande. L’article illustre l’effet magnétique d’interaction ainsi que les effets de la température afin de mettre en avant la signification d’une protection magnétique.

Share: