All Flex Acquisitions, a manufacturer of flex circuits and flex circuit assemblies, has presented the product line including flexible circuits that are single sided, double sided, and multilayer up to six layers at this year’s electronica in Munich. All Flex is a privately owned company located in Northfield (Minnesota, US). EPP Europe spoke to Dave Becker, Director of Sales & Business Development, about his plans for the European operation.

Mr. Becker, you’ve come to electronia in Munich for the first time as an exhibitor. What are the reasons for that?

All Flex has grown to nearly US $ 20 KK by focusing on low to medium volume flexible circuits and assemblies in the US market. We believe the European market is similar to the US market since many of the highest volume applications have gone to Asia, but there are many smaller manufacturing companies that need good applications engineering support for high quality flexcircuit assemblies. We believe an ocean isn’t much of a barrier in the hyperspace world today. The response we received at Electronica was very encouraging.

What are your plans for the European operation?

For our European marketing initiative we will expose our capabilities to European customers in several ways. We use the internet as a method of advertising and positioning our company with search engines. We have also hired a European marketing firm to assist us with establishing a presence. They have translated some of our technical articles, helped us with news releases, and have exposed our product capabilities to potential customers. They have also helped define how we capture and support new customers. And finally, we have begun attending European trade shows. All Flex has received a very favorable response during our initial two shows and will include plans for additional shows in our 2009 budget.

The All Flex European manufacturing initiative will be similar to our US recipe. In the US we follow a ten point continuous improvement effort we call Allflex Jump Start. We will use the same method in Europe. All Flex provides intensified customer support during initial part number design and delivery. The Jump Start process spans multiple departments with performance measurements for several metrics. The ten points are listed below:

1. Respond to all inquiries within 24 hours 2. Optimize conductor pattern for product reliability and manufacturability 3. Provide CAD data to customer for approval 4. Prototype tools = serial production tools 5. Short cycle fabrication time 6. 100 % engineering design review 7. First article inspection 8. Communicate shipment tracking information 9. Review initial run results and capture lessonslearned 10. Send out customer satisfaction surveys

Which parts do you target?

High reliability applications in military and aerospace and medical markets are 60 % of our present business. Instrumentation, industrial and consumer/automotive markets also represent substantial revenue. Our product offers reduced weight and space, and electronic packages across all market segments are seeking this property.

What kind of product did you showcase in Munich?

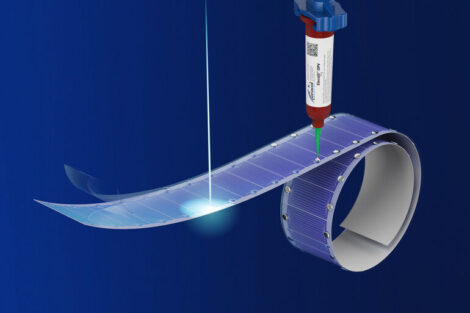

We introduced a new product, flexible heaters, at the Munich show. These are products very similar to our flex circuits but are produced with higher resistance metals and generate heat. We produce these parts with short delivery times to support development requirements and multiple design iterations for new customer projects.

We also build single sided, double sided, and multilayer flexible circuits. All Flex has two SMT lines to provide component assembly on the circuits we supply.

What are its advantages and benefits to the European users?

Advantages of flexible circuits and flexible heaters include:

- Eliminate bulky wire harnesses. Weight and volume reduction of > 70 % is possible.

- Eliminate assembly errors. Circuits can foolproof an assembly process and are electrically tested by the fabricator.

- Increased reliability and longevity in applications with continuous movement (printers, disc drives, cell phones, etc).

- Low dielectric constant and planar conductors provide signal integrity in controlled impedance applications.

- Precise and repeated conductor patterns allow predictable noise control, shielding, and crosstalk elimination.

- Thermal dissipation. Flat conductors and attachment to metal stiffeners work well to improve heat management.

- Elegant design. Eliminate wires, connectors, and hardboards into a single well-engineered packaging solution.

What were the drivers behind it?

Cost is always a critical driver. I tell customers they need to take advantage of the flexibility of the product. By bending a flexible circuit, wires and connectors can be eliminated and a more reliable and repeatable interconnect solution is provided. The use of flexible circuits in all types of electronics has exploded over the past 5 years into a multi-billion dollar market.

Can you tell me something about your company?

We have doubled the size of the company in the past 4 years by providing a high level of technical and applications support for this niche technology. All Flex builds a wide range of technically challenging flexible circuits including very long circuits (10 meters in length) and power conductor circuits (with copper thicknesses up to 250 microns). We also focus on building parts quickly. Standard delivery lead times are 2 to 3 weeks.

What do you manufacture?

The All Flex product line includes flexible circuits that are single sided, double sided, and multilayer up to six layers. We also specialize in complex flex circuits including Maxi-Flex, (40 feet+), Sculptured Flex, All Flex Power Flex (high current thick copper application) and Flexible Heaters. Materials types include Polyimide, Flame Retardant, and Polyester Flexible Circuits. All Flex has been manufacturing polyimide and polyester flexible printed circuits for 17 years and is a leader in the flex circuit industry in the area of quickturn prototype and low to medium volume processing. All Flex is ISO 9001: 2000 Certified, Mil-P-50884D Qualified, and ITAR registered. Flexible circuits from All Flex can be manufactured for RoHS Compliance and UL Certification. All Flex also has the ability to provide their flexible circuits with assembled surface mount and thru hole components. Additional value add capabilities including folding and electrical testing.

Which parts of the world are the current star performers for you?

Our marketing efforts have been limited to North America, so most of our sales have been to the US. We are, however, supplying circuits to a global community. We currently provide parts to Asia and Europe, but have targeted Europe as a market for growth. We are promoting ourselves with a European marketing firm, advertising on the internet, and attending trade shows as we seek to expand our global footprint.

Can you describe the service and support network your company offers in Europe?

Our technical and engineering support are located at our factory in the US. Order status from our Customer Service department is provided directly from the factory. We encourage direct communication with our factory so any answers we provide regarding orders, designs, deliveries, or issues are real time. We also employ a European marketing firm that assists as necessary for any special communication requirements. (jau)

EPP Europe 522

Share: