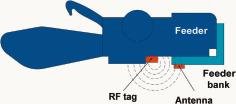

The key to implementing low-volume manufacturing is the time-to-market, the efficiency of product releases, and, most importantly, the fast production changeover. Since so-called “security & safety” products focus on absolute reliability (zero defect). It is absolute necessary to be able to have an error-free production process with documented evidence. Board assembly is still moving towards closed-loop intelligent feeder systems, providing a traceability function. Such feeder systems ensure that the correct component is loaded and consequently placed on the PCB, all verified. The feeder is continually communicating with the system – only when component, feeder and position have been successfully controlled in real time will the head pick and place the part. Upon removal or replenishing reels, the user is required to verify the feeder to confirm the proper component installation prior to picking any device. The traceability function logs the lot number (or reel manufacturing code) for the individual boards. This data is then stored in a database file which is easily transferable to the factory’s ERP (enterprise resource planning) system. Juki offered its first “intelligent” feeder system some years ago, and received positive reviews. Now, the company presented the third generation of their intelligent feeder system (IFS-X), breaking new ground by using RFID (radio-frequency identification) technology as the communication method between feeder and system, eliminating physical contacting. The storage medium on the feeder is passive, removing the requirement for electrical power. The RFID feature can also easily be retrofitted to existing feeders. The closed-loop recognition system offers a wide range of capabilities for a fast and secure feeder set-up as well as the traceability option.

EPP EUROPE 426

Share: