Since 1957, IPC has supported the electronic industry with standards to assist companies and individual operators in producing electronic hardware at a high-quality level. For many decades, IPC standards were considered “North American standards” but since the early 1990s, they have spread to all parts of the electronic world. The question now is: what benefit do IPC standards have for the electronic hardware supply chain?

To provide answers to that question, several companies in Europe representing electronic design, CAD, bare board production, assembly and soldering explain how they use IPC standards in their daily business routines.

This is the second article in a series and will cover bare board PCB supplier, the NCAB Group, with headquarters located in Stockholm, Sweden.

IPC standards was not the first choice

NCAB Group was founded in 1993 and has its roots in a Swedish-owned bare board factory in Malaysia and a sales organization in Sweden. The company, over time, changed its strategy and is today an integrated PCB producer, taking total responsibility for the entire PCB delivery process. Today, the company group has approximately 25 bare board factories in Europe and in the Far East. With 12 subsidiary companies located in different European countries and China and 135 employees, it is one of the largest suppliers of bare boards in Europe and delivers more than 45 million bare boards annually.

In the early ‘90s, IPC standards in Europe and particularly in Scandinavia were relatively unknown. The dominating standard for bare boards at that time was PERFAG, developed and published by the Danish bare board association. Therefore it was natural for NCAB in its upstart phase to use Perfag as their company standard. In 2002, the company realized that they needed a more current, relevant and well-known standard to fulfill its high quality and reliability requirements for European customers. The choice was easy since IPC standards were well established with bare board manufactures in China, where the company had its main factories. At the same time, large OEM companies in Europe started outsourcing , and needed an international standard to refer to when purchasing large contracts for electronic hardware. With its comprehensive program covering the complete electronic hardware chain, IPC was the ultimate choice for the company group.

Use of IPC standards on the bare board supplier side

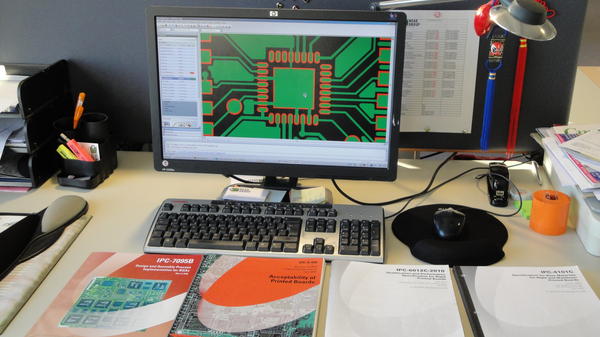

For NCAB, all of their bare board factories must produce boards that do not create any problems during assembly and soldering. It is even more essential that the customer don´t have to do any costly touch up or repair due to faulty bare boards. To eliminate that risk, the company requires that all their existing bare board factories use the following IPC standards in their production process:

The IPC-6010 series, family of board performance documents. The standards provide surface plating/coating criteria, hole plating integrity requirements, solder mask and covercoat coverage requirements and quality assurance provisions that include verification sample frequencies and lot inspection. The company uses IPC class 2 as the default with exceptions for plating, which is always class 3, and cleanliness reinforced from 1.56 to 1.0 µg/cm². It has developed its own classification for verification and requires two microsections per lot.

IPC-A-600H, Acceptability of Printed Circuit Boards. This 4-color guide provides illustrations and photographs of the target, acceptable and nonconforming conditions that are either internally or externally observable on bare boards. The company wants to ensure that operators, inspectors and engineers have the most current industry consensus information on both the supplier and customer side.

- IPC-4101C, Specification for Base Materials for Rigid and Multilayer PCBs. Covers the requirements for base material that are referred to as laminate and prepreg, including base material for lead-free processes.

- IPC-840E, Qualification and Performance Specification of Permanent Solder Mask and Flexible Cover Materials.

- The IPC-4550 series, Specifications for ENIG (Electroless Nickel Immersion Gold), Immersion Gold and Immersion Tin.

- J-STD-003B, Solderability Tests for Printed Boards. Prescribes test methods, defect definitions and illustrations for assessing the solderability of bare board surface conductors, attachment lands and plated-through holes utilizing either tin/lead or lead-free solder alloys.

- IPC-4761, Design Guide for Protection of Printed Board Via Structures. Provides designers and manufactories with detailed information on all existing methods for protecting vias on PCB via tenting, plugging, filling and capping.

- IPC-609A, Marking and Labeling of Components, PCBs and PCBAs to Identify Lead (Pb), Lead-Free (Pb-Free) and other Attributes.

- IPC-1601, Printed Board Handling and Storage Guidelines. This document gives guidelines for protection of bare boards from contamination, physical damage, solderability degradation and moisture uptake.

A majority of NCAB´s European customers must comply with the RoHS Directive and its requirements regarding banned flame retardants and lead. Since the RoHS Directive has had major exemptions like categories eight and nine (currently being phased out) plus military, avionics and space, NCAB is very precise in specifying what is needed and that their factories understand RoHS compliance.

Promoting to its customers and audits its suppliers

For those who have experience in the electronic hardware production chain, the perfect solder joint is the most important part of a bare board. If you provide a bare board factory with poorly designed data and/or a not suitable base material specification, the delivered bare board will not have the perfect solder joint as an end result. With this in mind, the company strongly recommends their customers use base material that is in accordance with IPC-4101C. If a customer requires IPC class 3 for its bare boards, the NCAB CAM department always inspects the incoming data (Gerber files) against the IPC-2220 board design series and its class three requirements.

The company sees itself as the key in providing solutions so all three parties (factories, customer and NCAB) can have optimal results and create perfect solder joints at minimal cost. The used method can be broken down into several steps:

- Education of all sales and technical personal at all subsidiaries in Europe and China in IPC standards and its different classes and levels.

- Inform all customers of IPC-sponsored seminars, workshops and technical meetings on IPC standards and their place in the electronic hardware production chain. The company also hold its own customer seminars that promote IPC standards and information.

- Assurance that new and existing NCAB bare board suppliers are following IPC standards requirements via an audit procedure. All factories producing bare boards are audited regularly to ensure high quality and reliability. When approving a new factory, the company performs factory audits and bare board samples are tested in the NCAB laboratory in Sweden, with tests made against IPC-A600G and J-STD-003B for solderability.

Benefits of using IPC standards

When the number of bare board functions increases, complexity and cost increase significantly. Combine the price of a bare board with other sophisticated components including assembly and soldering and you get an expensive product. With this in mind, the company is very conscious that an improperly designed and produced bare board can cause financial disaster its customers.

For NCAB Group, IPC standards have been successful tools for more than 15 years. IPC standards not only increase quality and reliability, the standards also make it easier for the company to communicate with both its suppliers and the end customers located around the world.

productronica, EW.WE-2

Share: