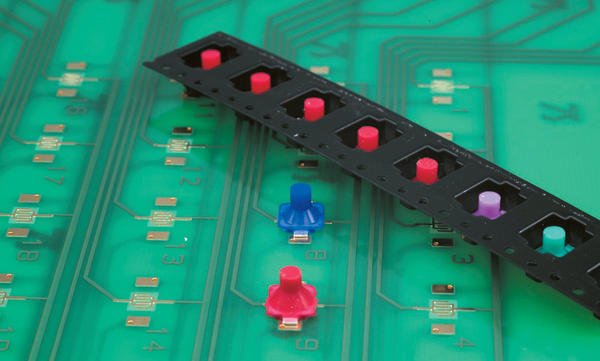

The new types of SMD-silicone keys of Abatek offer manufacturers and developers new scopes for design, cut the costs for prototypes and reduce the time of development. Abatek delivers within 7 days prototypes with customer-specific features, which are picked & placed and soldered in the reflow oven together with other SMD-components at the highly flexible pick & place machine of Essemtec. The silicone keys do not differ in the function from the known silicone keypads. The tactile feeling is exactly the same, the lighting can be integrated into the key and the stroke and the height of the key can be also adjusted to the production requirements. The favourable differences are the reduced time for acquisition, the higher flexibility during product design, by the no longer valid tooling costs for prototypes and the possibility of the full-automatic assembling with a SMD-pick & place machine.

Abatek can manufacture SMD-silicone keys within a few days, whose features are corresponding to the guideline of the customers. The height of the keys, the stroke, the actuation force, the colour and the type of the contact pills are some examples of the parameters to choose. More than 1 million combinations are actually possible. The keys can also be fitted out with an additional capacitive switching function, in order to cause an event, for example, already by approaching them.

Essemtec, the Swiss manufacturer of high flexible production systems for electronics, has optimized the pick & place machines for the processing of the new silicone keys in team work with Abatek. As from now, the automatic insertion of all entry key types at all pick & place systems of the FLX-, CSM- and Pantera-series is possible. Tape feeders with enough pocket depth are deliverable as standard and for prototyping flexible tape strip feeders are available. The maximum height of the components of the above-mentioned machines is at 15 mm and the clearance zone below the printed board at up to 40 mm. Thus enough space to insert silicone keys even on the front- and rear side of a PCB. The keys themselves resist the solder temperature smoothly, even at several carry outs.

The silicone keys are processed with an especially developed vacuum tool therefore, which picks up the entry keys safety from the belt or the pallet and places it exactly at the printed board or flex board. The vacuum tool of Essemtec can be used for all types of prototypes of Abatek. For example keys with different height can be placed with the same tool at the same product. If necessary, e.g. the customer needs a very specific form of keys, the Swiss manufacturer is able to adjust the vacuum tool in no time, correspondingly.

EPP Europe 532

Share: