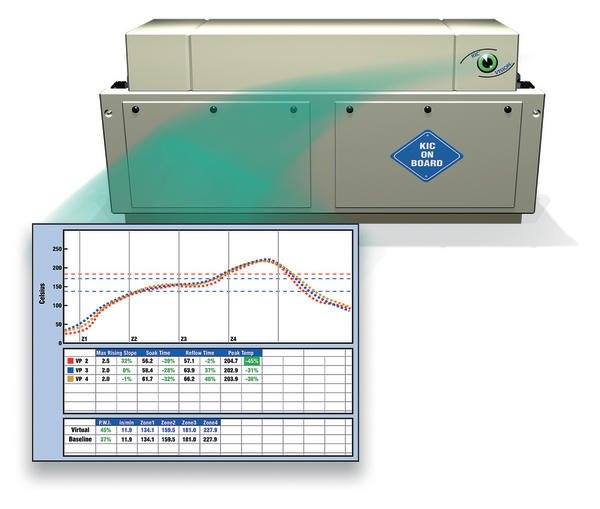

KIC Vision, an automatic profiling system from KIC, is designed for those customers that want to eliminate the manual tasks associated with periodic profiling for their reflow ovens. Although such profiling has been important for production quality as well as process documentation, many electronics manufacturers are burdened by the negative effects of such manual tasks.

These negatives include interruption to the production flow, expense in terms of labor and material, error-prone measurements, and the fact that infrequent profiling makes for poor quality control. Priced comparative to a manual profiler, the system provides the best of both worlds: It runs in the background continuously and automatically, and it provides sought-after profiles as frequently as once an hour. The system relies on embedded sensors in the reflow oven and the proven Virtual Profiling software to accurately measure the product profile.

After a baseline profile, the product profile is automatically measured and logged in the computer without any further manual input. The measured profile data includes all pertinent process data such as peak temperature, soak, fit to process window and more. The user may select the frequency of the automatic profiling from one profile in per hour increments up to once a week time slots, in one-hour intervals.

EPP Europe 454

Share: