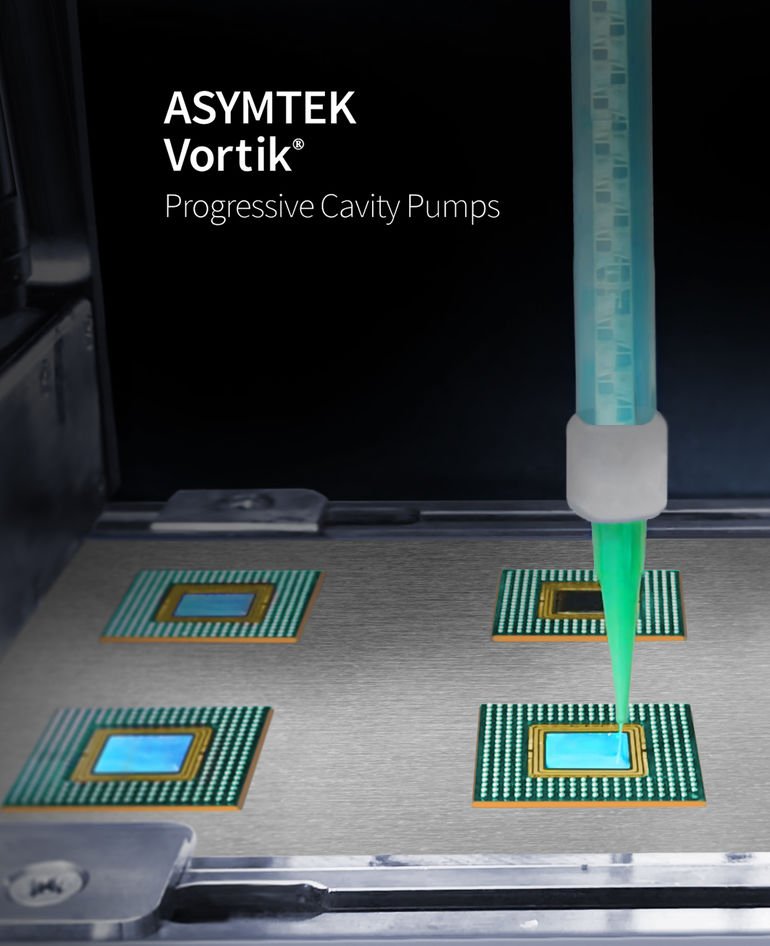

Asymtek, a part of Nordson Electronic Solutions- a global leader in electronics manufacturing technologies, brings its latest fluid dispensing and conformal coating solutions to IPC Apex Expo, San Diego, CA. New at Apex is the Asymtek Vortik family of progressive cavity pumps (PCP), with the smallest depositions possible on the market today. The VPs, VPm, and VPg pumps rely on positive displacement to provide continuous needle dispensing of one- and two-component fluids with high-volumetric accuracy, increased reliability, and reduced cycle time. At 0.2 microliters per second, the Vortik VPs offers the lowest flowrate and smallest depositions possible across all PCP pumps available in the market today – delivering precise control of narrow lines and small shots for two-component mixed fluids.

Another first at the tradeshow is Vortik‘s advanced calibration assist with patent-pending ARC technology that ensures high volumetric dispense accuracy for one- and two-component applications. Software-based ARC technology takes the guesswork out of application setup. Optimal settings can quickly be determined, such as mix ratios, without manual calculations or time-consuming test iterations.

Shown for the first time in the USA is the Qadence closed-loop flow control system in the company’s EasyCoat 6 software. This system maintains a stable flow rate by volume for high-quality conformal coating results by automatically compensating for viscosity changes related to temperature, humidity, and batch-to-batch variation. The Qadence system lets you quickly calculate a target flow rate and set process limits with an EasyCoat control routine called the Flow Calculator (patent pending). With the Flow Calculator, a typical 1-hour setup can be completed in 30 minutes and a 30-minute setup in less than 10 minutes.

On display will also be the Panorama C-Line for advanced process control in conformal coating. Panorama C-Line components fit seamlessly together to deliver a complete, turnkey solution for coating and curing, with closed-loop controls and data to fuel continuous process improvement. The C-Line will feature a fully integrated Asymtek select coat SL-940 with a triple-valve configuration and an Asymtek FX-940 automated coating inspection system. Visitors can experience a 360 ° virtual reality tour trip of the Panorama conformal coating line at the company’s booth.

Additional products on display will include:

The Forte Series dispensing platform with Forte Max dual-head, real-time skew correction. The new precision dispensing platform includes a dual-simultaneous dispense head with two high-frequency IntelliJet jetting systems that dispense at the same time to further boost UPH and quality outcomes. The system reduces dispense time by half and automatically adjusts for workpiece and individual component rotational skew.

The Quantum in-line and batch system which delivers uncompromising quality, value, and productivity for demanding fluid dispensing applications. The system will feature the Vortik VPm progressive cavity pump for bonding, sealing, encapsulation, and potting applications.

The Helios SD-960 series featuring a two-component thermal interface material application and a new dual-drawer configuration is ideal for batch manufacturing. Dual drawers allow the first substrate to be dispensed while a second is loaded.

The DIMA C-Turn Flux automates flux dispensing in combination with automated hot bar reflow soldering. It is the ideal solution for LCD solder attach, wire solder attach, and connector and component solder attach applications.

„For 35+ years, Asymtek has focused on possibilities, continually innovating as technology and electronics evolve,“ said Peter Bierhuis, president, Asymtek products. „By focusing on what‘s possible, we bring more to our customers through innovative solutions, customization, application expertise, and award-winning global support. We hope attendees will visit us at our booth to discuss how our solutions can enable their innovations.“

Apex, Booth 1611

Company contact

Nordson Asymtek

2747 Loker Ave West

Carlsbad, CA 92010–6603 USA

Tel.: +1 (760) 431–1919

E-Mail: tech.europe@nordson.com

Website: www.nordsonasymtek.com

Also of interest:

Conformal coating line from Nordson Asymtek has optimal efficiency