Hoang PVM Engineering has reflected on the changes made to its patented Memory Back-up Unit (MBU), PCB support module, over the past 14 years. The company says it is wants to pass on to other users the suggestions made by its SMD customers as well as via its own practical experience.

Background

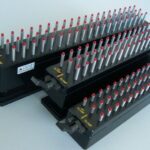

Since the end of 2008, the MBU has been used to provide circuit board support and prevent the bending of subassemblies during the printing process loading. It comprises stable fixing magnet and an extensive number of pins which function to support the circuit board over its entire surface.

The company points out the importance of the Jig unit, which can control and memorize the multi height of the set pins, meaning it can be quickly installed and set up precisely.

Double-sided assemblies

According to the manufacturer, the unit is ideal for double-sided assemblies because it eliminates the time-consuming placement of supports and increases line yield as paste application can be better controlled.

“Since MBU modules remain permanently in the pick & place machine and screen printer, they are easily removable, since no compressed air or electricity is necessary,” Hoang explained. “It is also ideally suited for the single-sided printing of printed circuit boards. The time-consuming and cumbersome installation of every product change in order production is now a thing of the past, which is an enormous time and cost optimized.

Customizable

“Companies can determine the entire configuration of their MBU modules. This includes the free selection of the dimensions as well as the number of mounting with support pins. This allows for the product to be adapted for almost any application. It is easy to combine the modules for large circuit boards.

“As always in e-production, as long as we work, we make mistakes, making mistakes is human, but our task is not only to learn from the manufacturing errors, but also to push the errors outwards and according to technical possibilities.”