An automated smart factory has now become more important than ever before since the spread of Covid-19. Electronic manufacturers have had to learn how to modify their processes to be more resilient, by making significant changes to their productions. The EPP Europe team spoke with Gabriela Reckewerth, the Senior Director Global Marketing from ASM SMT Solutions, and discussed how the company has been affected by this year’s uncertainties and the changes they have noticed since the start of the pandemic. She further explained their commitment to their customers, even with the various restrictions set in place and their thoughts about the future market.

What has the company focused on for 2020?

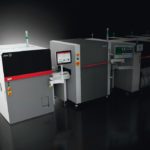

We continued following our innovation roadmap in 2020 and kept working on our developments for the integrated smart factory. The new Release 2020, which we presented in a major livestream event due to the coronavirus crisis, includes several innovations for our customers. For example, we introduced a new generation of the Siplace SX. With new placement heads, an open interface for connecting specialty feeders from third parties, new station software and a whole lot more, the Siplace SX has enhanced its position as a powerful solution for high-mix manufacturing environments even further. Other releases include the DEK TQ high-volume printer with more than 8 hours of ‘non-stop production’ and many innovations in our software solutions. The most important innovation in the software field is our smart factory suite called ASM Works.

The pandemic has also posed new challenges regarding the ways in which we interact with our customers. Thanks to our advanced remote-service infrastructure, we were able to provide help quickly, and in most cases without having to even be on-site when something had gone wrong or the production had to be expanded. Currently, we are working with our customers to make their manufacturing and business processes even more resilient. With our know-how and as the world’s largest equipment supplier to the electronics manufacturing industry, we are for many customers the supplier of choice when it comes to getting reliable support. While many suppliers were often involved with themselves, we were much more active and started many support programs for our customers. For example, with our “Time4Academy” initiative, we opened up our e-training platform to all customers for several months so that they could put the production stops during the pandemic to use by training their employees at no charge. This earned us a lot of praise from our customers, and the online courses and webinars at our SMT Centers of Competence were very well attended.

What are the advantages of ASM Works, and how does it differ from your other software solutions?

To network and integrate a production, you had to purchase, install and maintain many different software options until now. Projects to network your electronics production often failed because of software compatibility problems, which was not only troublesome but also very expensive.

With our modular software suite of proven ASM software components, our customers can now build a solid foundation for their integrated smart factory – one that they can adapt in stages in accordance with their respective requirements and capabilities.

The ASM Works Core base module provides the architecture that enables machines to seamless exchange data right away. Even orders and setups can now be planned for the entire factory, resulting in optimized shop floor management. And with currently eight upgrade modules, more smart functionalities can be added at any time and in any order. Since ASM Works integrates the individual software components into an overall concept, electronics manufacturers no longer have to worry about interfaces, compatibilities, data transfers between lines, or licenses and upgrades. All components are managed from a single launch pad. General configuration settings, such as shift calendars or roles and permissions, are administered centrally and automatically transmitted to the individual modules. All this makes networking and integration much easier, faster, and more cost-effective.

How important do you find smart factory solutions, especially with the effects of the Covid-19 virus?

Companies that operate in a more connected and integrated manner have proven to be much more resilient and robust during the crisis. ASM’s concept of smart operator pools and our remote support solutions, for example, proved to be extremely helpful in minimizing personal interactions between employees in accordance with social distancing rules during the pandemic. Smart operator pools replace rigid team assignments, and the automatic transmission of data and information makes it much easier to work under pandemic conditions. I believe that there will be a huge boost in digital upgrades and modernizations after the crisis. In addition to efficiency and quality, companies will increasingly focus on resilience, a field in which ASM’s concepts for the integrated smart factory provide ways for making companies better and more robust in the ‘new normal’.

Where are the most effects of Covid-19 in business terms (i.e. in which country, but perhaps also in which segment)?

As a globally active group and technology leader in the field of SMT production, ASM was already positioned to master the extreme challenges of the pandemic thanks to its strategic alignment. Partly because of the unabated strong demand for electronic products, the crisis has affected us much less than many other industries. The same applies to the majority of our customers. Of course, every company has to contend with the new conditions, but many of our customers have developed creative solutions and are positioned better than their competitors thanks to their high degree of digitalization and automation.

The global easing of pandemic-related regulations has an effect as well. We are seeing significant growth in some major markets. China is an example of this. There is also a noticeable increase in demand in Central Europe, as evidenced in the utilization of our Center of Competence in Munich that is operating at full capacity with lots of visitors and appointment requests.

What would you convey or suggest to your customers on how to optimize their production?

Electronics manufacturers should keep transitioning to the integrated smart factory consistently and forcefully – maybe even accelerate the process. The pandemic has made it alarmingly clear how inflexible our old manufacturing concepts are and how quickly they lead to a dead end. The digital transformation, automation, remote access capabilities and smart operator concepts in combination with powerful and flexible machines and solutions make companies not only more efficient but much more resilient.

How does ASM see the developments of the future? What’s coming? Are there new developments planned for the company?

ASM’s claim of ‘Enabling the Digital World’ sums up our mission perfectly. After the pandemic, the need for a sustainable and comprehensive digital transformation will become even stronger. This applies to our customers as well as to our own processes. Fortunately, we are extremely well positioned for this with our innovation projects and the new solutions we have rolled out in recent years. What will change, however, is that resilience will be a new dimension in the customers’ purchasing decisions, also with regard to the selection of suppliers and the way in which the parties work together. Which suppliers can I really depend on even in extreme situations? And which of my suppliers can fully maintain the scope and quality of their services through modern digital concepts when the next crisis comes along? These are the new questions that customers will ask themselves, and we as the world’s largest equipment supplier and technology leader want to provide the best answers to them.

Thank you very much for your time Mrs. Reckewerth.

ASM Assembly Systems GmbH & Co. KG

Rupert-Mayer-Strasse 48

81379 Munich Germany

Tel.: +49 89 20800 27819

E-Mail: smt-solutions.de@asmpt.com

Website: www.asm-smt.com

ASM announces SMT production solutions in digital livestream