The core issue with today’s legacy material management systems is that there is no single responsibility to manage all materials in the supply chain across the whole operation. Traditional enterprise resource planning (ERP) systems generally cannot track materials effectively once they are moved to the production area, causing inefficient planning and ultimately costing money.

One of the key principles behind the innovation of Industry 4.0 is flexibility of planning, quickly adjusting production rates to meet changing demands from the customer. What is needed is a single point of management and accountability of all materials, no matter what they are or where they are, that is automated and digitally connected throughout the operation.

First steps to improving material management

Keeping track of inventory is a challenge in itself. Materials are received and stored in warehouses before allocation to production. Different materials may be stored in different warehouses depending on the type of material and the time it will be needed. Some materials that are located are on the shop floor to accommodate bulk delivery of a few high-use materials or to support an area of non-standard self-contained production, such as for new product introductions and small lot sizes.

The production area may include family setups, materials stored on feeders or on trolleys, and moisture-sensitive materials that need special handling, such as baking, and all of it needs to be accounted for in the overall inventory management system.

For inventory to be accurate, timely consumption information needs to be fed back to ERP so that the count of materials available recorded by ERP matches the physically available material. Only by keeping these records up to date can the orders and deliveries be on time and accurate.

What about unmanaged, partly used materials that accumulate on the shop-floor once work-orders are completed? They also must be included in the inventory management system with accurate data on how much material remains on each reel so that they can be quickly and effectively re-allocated.

In traditional manufacturing, ERP pushes materials to the shop-floor according to the master factory plan. The materials often are unmanaged and invisible in the supply-chain until a record of consumption is returned, calculated by counting the number of products made multiplied by quantities per product according to the original production bills of materials (BOM).

Legacy factory operations can immediately save money and time by optimizing their control of materials using lean, just-in-time (JIT) manufacturing practices. A lean “pull” signal can be derived directly from the machine operation, which means that kits of materials do not have to be prepared in advance; instead, all necessary materials remain in the warehouse ready for selection for immediate use on the machines and other processes.

An automated pull system knows what the manufacturing process is currently producing, because it is linked to the bill of materials. Work-orders, derived from ERP, are managed at the machine level. In an automated, comprehensive, and digital material management system, work-orders are set up for each instance of production of a certain quantity of a product. The machine program, setup and execution data, and documentation are assigned at each step in each work-order.

In this way, the exact routing of a work-order through multiple processes, each with their own execution instructions, can be known in real-time, including estimated start times, quantities, and run-times. The sequence of work-orders that will be executed can be viewed and tracked, which means the materials required for the current product in the current work-order are as well. With this, planning can be done accurately for changeovers that will take place for future products.

Verification of materials during the logistics process can also be done during the setup of materials on the machines. An automated, digital management system prevents the machine or any other process from working until all of the materials have been correctly set up, according to the requirement defined in the work-order. Unique material IDs and their associated attributes are verified against the assigned setup that is derived from the work-order.

This is far more comprehensive than simply checking the part number as done by many other solutions. For example, the MSD status is also checked, providing a warning and if necessary, preventing the machine execution, if contamination is likely to happen. This type of advanced verification process ensures that no mistakes in the materials setup are made, improving product quality performance while reducing scrap and re-work issues caused by incorrect material placement.

The final essential piece of information required for automatic JIT delivery of materials to work is a live, networked interface tying together the machine processes, through which the progress of production, in terms of the number of PCBs produced, is communicated in real-time, along with the actual usage and spoilage of each of the materials.

A digital material management system puts these pieces of information together to create the live just-in-time logistics schedule for materials to be selected from the warehouse and delivered to the machines, so that the right quantity and quality materials arrive, right on time.

Overcoming challenges today, and for the future

Let’s take a look at some specific challenges that can be addressed by an automated, digital solution such as Valor Materials Management. This is not only still available in the Valor Manufacturing Solutions suite of products, but it is now also available as part of Siemens Opcenter Execution Electronics solution for comprehensive electronics manufacturing management. These solutions have been proven to save money and time, as well as improve productivity in electronics manufacturing operations around the world.

Materials management and connectivity

Materials management can be tied easily into the Valor IoT Manufacturing hardware and software platform that connects machines from a wide variety of vendors and platforms to gather factory floor and operations data accurately in real-time, including from machines or manual processes that do not have a digital connection to the network.

Material delivery between workstations, including bare-boards, semi-assembled products, and finished goods, can be fully automated. Factories can adapt to high-mix/low-volume manufacturing by moving from “traditional” linear assembly lines to manufacturing, based on dynamic cells where products “hop” between cells as required. The solution integrates with smart shelves, material towers, and automatic guided vehicles (AGVs).

Integrating manufacturing analytics for materials

Integrated with business analytics, materials management can provide key metrics and operative guidelines to help improve profitability with dashboards, reports, and AI. Material insights can be extracted from the data and used for quoting, procurement, and supply-chain optimization. For management, material dashboards also can be used to better monitor and optimize inventory.

Traceability

Traceability and compliance are a valuable component of the materials management system. For example, this includes providing information on the date and time a reel is placed in and taken out of the machine, quantities of components used for a reel, and the date and time that a PCB assembly leaves the last machine.

Some real-world examples

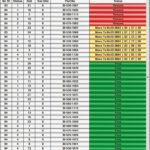

Stories from customers illustrate dramatically how optimizing material management can make a huge difference for a manufacturer. In one instance, a Chinese telecom factory decreased changeover time from an average of 150 minutes to an average of 40 minutes, and its PCB output increased from 240 to 305 PCBs per hour using the automated materials management solution.

In Japan, a factory increased machine working time by 20 % due to changeover, as well as significant cost savings per year. Their changeovers took 45 to 100 minutes, which was reduced to 12.5 minutes on average, with about 15 changeovers per day. After some time with the implementation, they reported further increase of productivity and high machine investment savings. Machine working time improved by going from 22-hour production with three shifts to 16 hours with two shifts. They were able to increase line utilization from 72 to 91 %, reduce SMT inventory by 15 %, remove most of the shop-floor material storage, and let the operators focus on increasing quality.

These examples show how upgrading to a legacy materials management system is a good investment, now and for manufacturing in the future, building in some needed business security as the global electronics market and supply chains are shifting and changing.

Sagi Reuven is a mechanical engineer who holds an MBA and is experienced in Mentor Graphics layout design and simulation products. Before joining Mentor, a Siemens Business, he was the CEO and co-founder of a medical device company in the retinal imaging sector and consulted for other start-up companies. Sagi is a part of the Siemens OpCenter-Valor business development team focused on electronics manufacturing.

Sagi Reuven is a mechanical engineer who holds an MBA and is experienced in Mentor Graphics layout design and simulation products. Before joining Mentor, a Siemens Business, he was the CEO and co-founder of a medical device company in the retinal imaging sector and consulted for other start-up companies. Sagi is a part of the Siemens OpCenter-Valor business development team focused on electronics manufacturing.Zusammenfassung

Nachdem die Materialkosten in der Elektronikfertigung einen sehr hohen Anteil der Produktkosten ausmachen, wird durch Beispiele gezeigt, wie lohnenswert die Investition in ein neues Materialverwaltungssystem ist.

Résumé

Alors que les frais de matériaux représentent une part très importante du coût des produits dans le secteur de la production de composants électroniques, des exemples mettent en lumière l’intérêt d’investir dans un nouveau système de gestion des matériaux.

Резюме

Поскольку материальные затраты в значительной мере отражаются на стоимости электронной продукции, в статье приводятся примеры, показывающие, насколько выгодно инвестировать в новую систему управления материальными ресурсами.

Mentor Graphics Corporation

8005 SW Boeckman Road

Wilsonville, OR 97070 USA

Tel.: +1 (503) 685-7000

E-Mail: sales_info@mentor.com

Website: www.mentor.com