The machine-to-machine (M2M) communications, guided in part by Industry 4.0, are quickly changing the manufacturing process by aggregating process data such as first pass yield and throughput. Koh Young is strengthening its large-scale datasets using the highest quality data captured through its 3D metrology expertise, then the AI algorithms necessary for smarter manufacturing processes are trained by utilizing the datasets. As part of this mission, Koh Young is dedicated to adapting AI technologies to inspection technology across a multitude of developments.

What is AI?

Artificial Intelligence is a multidisciplinary field of science where the goal is to create intelligent machines by making things “smarter”. Historical applications of this goal include natural language processing and translation, visual perception, pattern recognition, and decision making, but the number and complexity of applications have been quickly expanding. Out of all the advancements researchers have made, the current driver of the AI inflection point is thanks to major advances in deep learning.

Deep Learning, which is a subset of machine learning, is an algorithm with a hierarchy of “deep layers” of large neural networks fed by data without feature engineering. The company is also applying deep learning with its AI engine, solving problems that are difficult for experts to model. From practical solutions like Koh Young Auto Programming (KAP) and Koh Young Process Optimizer (KPO) to improvements in measurement quality and inspection accuracy, the company has been utilizing AI to meet the rising difficulty in the SMT industry through its KSMART solution.

Value of accurate 3D Data

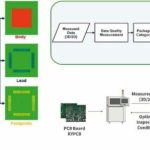

Data is the most crucial element of the success of the AI solutions. Deep learning effectiveness is linked to the quality and quantity of the input data to address many different requirements from a numerous number of fields. The use of AI to provide smarter inspection systems has been desired by every inspection provider. However, it has been difficult to realize due to the limitations of 2D imaging, which was the de facto standard for the past 25 years. Not only is it difficult for 2D Automated Optical Inspection (AOI) systems to identify defects on curved and reflective solder joint, 2D AOI systems cannot generate reliable data. Every aspect of 2D inspection relies on 2D features like contrast; thus, it is extremely challenging to correlate with to the quantitative measurement of 3D objects.

The company, however, measures the 3D information of the components and solder joints. Their AOIs offer the most valuable and reliable measurement data, so they become the most reliable “sensor” on the line. The validity of 3D data is guaranteed as the company uses 3D technology for all components types to extract the exact body dimensions, unlike other system that use “blob detection”, which may be susceptible to external factors like board warpage and component proximity. The combination of measurement and process data piles collected from its SPI and AOI systems, as well as from printers and mounters, allows Koh Young to deliver advanced AI features with reliable “big data”. Indeed, the quality of data is more important than the quantity of data to create effective and reliable solutions with high value proposition.

Measurement getting ever more accurate

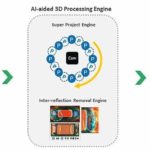

So how does Koh Young use AI? It all begins with solving inspection challenges of SMT assemblies. The solder and components on finished boards have many specular surfaces, which will reflect some light back to camera, while creating strong inter-reflection with other lighting reflections. Since some of the reflected light does not reach the camera, they generate false signals which may cause measurement value errors. This specular reflection issue is becoming more troublesome, in relation with increasing board density and decreased component spacing.

The company uses AI to prevent measurement errors by incorporating learning in the product. The hybrid fusion of an analytic approach which utilizes a mathematical measurement model and AI which is used for learning abnormal symptoms from the combination of good and bad measurement data, allows Koh Young to detect and eliminate abnormal measurements, which reduces false calls and escapes. Through the hybrid fusion approach, the measurement accuracy only gets better against many different challenges.

Share knowledge between lines

Another area where the company has been proactively applying AI is with AOI programming. With the help of deep learning methods using true 3D data, the assignment of components on a PCB is gradually becoming autonomous. The Koh Young AI-powered Auto Programming (KAP) system proposes the recommended inspection conditions based on 3D measured data, which not only simplifies inspection condition programming, but also makes it faster and more consistent with the best mapping conditions.

KAP reduces job preparation by up to 70 percent, which makes it an ideal solution for high-mix, low-volume or time-sensitive applications. Moreover, their prediction and decomposition engine allows components to be categorized by lead count, component type, measurement score, and more. These elements further help cleaning, parsing, enriching, and shaping the data, which plays a major role in AI empowerment. Going further, the company will apply AI for pad grouping and inspection condition tuning, while incrementally learning new packages at new sites.

Improve yield and process optimization

With increasing component miniaturization, improving inspection quality, and increasing inspection system throughput programming is paramount in the manufacturing industry. These needs are increasingly fulfilled with more computational power, which then yields even better inspection solutions. AI implies that such improvements can be fulfilled quicker with machines that continuously learn to solve new problems. However, the main challenge is complete end-to-end optimization. Harnessing the power of its own AI solution, the company has developed Koh Young Process Optimizer (KPO) solution.

KPO is the company’s smart factory solution driven by AI to control and optimize the printing and mounting operations. KPO heavily relies on accurate 3D measurements data and error detection from SPI and AOI machines, which sets the stage for smart factory solutions.

The KPO printing solution includes three interlinking modules that exercise complex algorithms to develop closed-loop print process recommendations, which are namely Printer Diagnosis Manager (PDM), Printer Advisor Manager (PAM), and Printer Optimizer Manager (POM). The enhanced AI engine actively optimizes the printing process by combining real-time printing and SPI measurement data. PAM automatically performs DOEs designed to perform a detailed SPI result analysis using advanced diagnostic algorithms and noise filtering models, and then recommends the ideal print parameters. PDM uses multiple anomaly detection algorithms to actively optimize the print process and further reduce false calls. The final module, called POM, uses the Koh Young adaptive learning engine to generate models and fine-tune process parameters. While each module provides inherent standalone process benefits, the combined power of the three modules ensures the highest process reliability and production flexibility while reducing dedicated resources and expertise.

The KPO mounting solution includes three modules called mounter advisor, mounter diagnosis, and mounter optimizer. Mounter advisor studies and analyzes the offset distribution of the major mounter elements and differentiates these offsets from the component offsets measured by the pre-reflow AOI system. The system will automatically identify mechanical and software mounter failures, as well as the root cause(s). The mounter diagnosis and mounter optimizer modules are currently being developed in collaboration with our mounter partners. These solutions will recommend ideal component placement positions by utilizing SPI, pre-reflow AOI, and post-reflow AOI data, all the while automatically notifying technicians and engineers about mounter issues in real-time during production.

Conclusion

Artificial intelligence and its associated benefits will help advance the manufacturing industry confront challenges like the lack of skilled manpower and cost of minimization. Koh Young is focusing on using an AI-based solution as the primary vehicle to enable the future of electronics manufacturing.

As the inspection market and technology leader, the company is using its AI solutions to achieve its vision with a focus on next-generation cooperative efforts that expand process capabilities and factory performance. To realize this plan, Koh Young has established three additional R&D centers to generate a quantum leap in technological leadership and competitiveness. The company can apply its AI solution to its current areas of expertise while paving the way into new markets and industries beyond SMT.

Koh Young Technology Inc.

14F Halla Sigma Valley

53 Gasandigital 2-ro

Geumcheon-gu, Seoul 08588 Korea

Tel.: +82 2 6343 6000

E-Mail: info@kohyoung.com

Website: www.kohyoung.com

Künstliche Intelligenz und die damit verbundenen Vorteile helfen der Fertigungsindustrie, Herausforderungen wie Kostenminimierung oder dem Mangel an qualifizierten Arbeitskräften entgegenzutreten. Die Titelstory zeigt, wie der Einsatz KI-basierter Lösungen die Zukunft der Elektronikfertigung ermöglicht.

L’intelligence artificielle et les avantages qui y sont associés aident l’industrie manufacturière à relever des défis tels que la réduction des coûts au minimum ou l’absence de main d’œuvre qualifiée. L’article à la une montre comment l’utilisation de solutions basées sur l’IA rend possible l’avenir de la production électronique.

Искусственный интеллект и связанные с ним преимущества помогают промышленному производству решать такие задачи, как минимизация затрат или нехватка квалифицированных рабочих. На титульной странице статьи рассматривается, как использование решений на основе искусственного интеллекта обеспечивает будущее производства электроники.