Manufacturers of electronic assemblies currently face numerous challenges. These include the miniaturisation of components, an ever-increasing PCB component density and a growing variety of different assemblies. In order to retain an overview of these developments and still be able to continuously improve processes in assembly production, traceability and precise process data documentation are becoming more and more important. Traceability has long been an integral and indispensable part of machine soldering processes such as reflow, wave or selective soldering. More than half of all newly-delivered systems are equipped with a network connection and the software necessary to enable traceability in real time.

Traceability is quite different when it comes to the rework of assemblies, e.g. after the machine soldering process. To correct faulty automated solder joints, either a manual soldering process or a rework system is used, depending on the type of component. As soon as a soldering iron is employed to carry out such reworkings, however, the comprehensive documentation of the entire soldering process was, at least until recently, rendered impossible as manual processes could not be included in traceability systems. For this reason, many manufacturers completely dispensed with manual soldering processes or only permitted them when elaborate special approval has been granted. This has often resulted in complete assemblies being scrapped if just one faulty solder joint is discovered. And of course, for both economic and environmental reasons, this is something that should be avoided at all costs.

Documentation at every stage

To guarantee traceability, even of manual soldering, each individual soldering process must be precisely documented. Among other things, the assembly to be processed, the materials used (such as soldering tip, solder wire and flux), as well as process temperature and soldering time must be recorded electronically and made available for tracing.

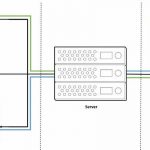

With the i-CON Trace, Ersa has developed the first soldering station specifically designed for complete traceability in manual soldering for use in a digitally-networked environment. The system comes with various connectivity features including WLAN and Bluetooth. If there are restrictions on wireless transmission methods at a particular production site, a wired connection is also available as an option (in this case, a network card is used to connect the soldering station to a server via a network cable).

The software for operating the soldering station is available as a download free of charge and does not have to be installed on each individual PC or end device (as was previously the case). The software, called ‘Ersa Trace Cockpit’, need only be installed once on the customer’s server and as soon as a soldering station is integrated into the company network, all mobile end devices (PC, tablet, smartphone) that are on this network, and have the appropriate authorisation, can access it. Access is easy via commonly used web browsers such as Google Chrome, Firefox, Windows Explorer.

New levels of connectivity

The connectivity of the station elevates manual soldering to a new level. It allows for the process to be transparent, traceable and enables documentation of each individual soldering process. The PCB, the component to be processed, the soldering tip used, the process temperature and soldering time are all recorded electronically and can be fully traced – both for manufacturers’ own documentation as well as for customers’. Tasks which were not previously possible or could only be reworked mechanically can now be processed manually without any risks.

The integration and saving of the soldering parameters used in complex, networked manufacturing processes which run via an MES (Manufacturing Execution System) is also possible as the stations can be connected to the MES. This means it is possible to download a recording of the entire soldering task via a desired file format and save this in a higher-level control system. For real-time communication between the soldering stations in production and the customer’s MES, the company offers the possibility of a customised solution by means of a gateway.

Another important feature is the ability to centrally preset all essential parameters of the soldering process for a specific soldering task by qualified personnel. In this way, a customer-specific soldering task can be created for a particular sensitive component or critical PCB and the corresponding parameters can be predefined. As soon as this component needs to be processed, the individual soldering task is automatically assigned, and the soldering specialist will only be able to start work when all the specific parameters for this particular component have been set. This significantly increases process reliability. The operator, now able to concentrate entirely on soldering, is less likely to make errors. Any faults such as a soldering temperature which is outside the process window, a defective heating element or an unsuitable soldering tip for the specific component, will be detected and displayed by the system.

The server-based software concept also makes device management much easier. Firmware updates, calibration intervals, and, in future, even soldering tip wear can all be monitored and individually traced. Since mobile devices on the network can communicate with every soldering station in the network, firmware updates are now child’s play. The firmware on each individual station can be updated with just a few clicks via a PC in the production manager’s office. The same goes for regular calibration intervals. Often individual soldering stations are calibrated at different times of the year. With the new system, calibration intervals are stored in the software and can be viewed for all soldering stations via a central PC and a reminder function can be enabled.

Smart operation

The second important feature of the system is its operating concept. With only one on/off switch and three LEDs, the interface of the i-CON Trace differs significantly from other industrial soldering stations which often have complex setting options and a display. As the software is centrally located on a customer server and not on each individual PC, access and operation is quick, easy and demand-oriented via any mobile end device.

Through the app downloaded onto smartphones and tablets, the i-CON Trace can also be used like a conventional stand-alone soldering station without a connection to a company network. The program for controlling the soldering station runs on the mobile end device. Important information such as set and actual temperature is displayed on the device (connected by via Bluetooth or WLAN) and can also be amended there, enabling demand-oriented, smart operation for the user.

Redesigned hardware

The system sets new standards not only in terms of connectivity and operating concept but also in terms of hardware. Both the heating element and the soldering tip of the i-CON Trace can be changed separately without any loss of performance. Reaching up to 150 W, the soldering iron provides a huge amount of power, and the new tips, which have been completely redesigned, deliver this power exactly to where it is needed: the solder joint. The fact that the soldering tip can be changed independently of the heating element means that each wearing part need only be replaced when necessary. This significantly reduces costs over the entire life-cycle of the soldering station – saving on materials and resources – and ensures the i-CON Trace brings not only economical but also environmental benefits to users.

Tips in all shapes and sizes

So operators can ensure they have the right soldering tip to hand for various soldering applications, Ersa offers tips in a variety of shapes and sizes, as well as customised tip shapes for special applications. ‘Tip´n´Turn’, the patented concept for joining heating element and soldering tip, enables tip change in record time. Each tip has a bayonet lock which, in combination with the multifunctional holder, allows the tip to be changed speedily and safely. The soldering iron including tip need only be placed in one of the openings provided and turned through approx. 10°. The old soldering tip can then be removed and a new, suitable tip can be fitted. This can be done by hand without the storage stand and even while hot.

The missing link

Ersa believes that with the i-CON Trace soldering station, the gap in traceability in electronics production has finally been closed, allowing for full traceability of the hand soldering process from now on. With the system’s unique software concept and intuitive and smart user interface, manual soldering processes are safer than ever before. Combined with the high level of power and the low operating costs, the i-CON Trace elevates the process of manual soldering to a whole new level.

Moving sustainably into the future

To mark the occasion of its 100th anniversary, Ersa will donate the proceeds of the i-CON Trace Rainforest Edition, limited to 300 units, to a sustainable rainforest project run by a large international aid organization.

Zusammenfassung Résumé Резюме

Eine Handlötstation verbindet manuelle Prozesse mit jeder digital vernetzten Produktionsumgebung, um so eine lückenlose Rückverfolgbarkeit zu gewährleisten.

Une station de soudure manuelle relie les processus manuels à chaque environnement de production en réseau numérique, garantissant ainsi une traçabilité sans faille.

Ручная паяльная станция соединяет ручные процессы с любой производственной средой с цифровыми сетями для обеспечения беспрепятственной прослеживаемости.