Founded in 1954 in Tokyo, Japan, the company has proven its ability to adapt to trends and expand into many incipient markets and technology segments over more than six decades. Their focus is to provide semiconductor test solutions across the memory and SoC tester markets, including AI, smartphones, automotive and display related industry segments.

In 2017, Advantest Europe GmbH with its headquarters in Munich, Germany, was recognized as one of Germany’s Best Employers 2017 by the internationally-renowned consulting firm, Great Place to Work. As an innovator, the European entities are focused on R&D and boast three state-of-the-art facilities with numerous other support sites across Europe.

Adapting to the future landscape of the electronics industry

As in the past, the company is looking forward into the future to anticipate and identify promising up-and-coming market trends that are currently showing potential or are already on the rise. One solid trend, for instance, is the demand for smart portable devices such as smartphones and tablets to deliver processing performance without significantly compromising battery life. A long battery charging interval is a huge differentiator that can make or break even the most promising products and technologies. Simply put, people demand a long battery life, but still crave faster, smaller, more feature-packed devices with power-hungry connectivity technologies like 5G. However, as is often the case, solving one problem produces another and the same applies to the development of more sophisticated devices, where testing, especially SoC testing, has come up against formidable challenges. These include higher voltages, data encryption, low leakage battery powered designs, more complex chips and rapid development cycles. However, test technology providers need to continue to meet the demand for low cost solutions in high volume manufacturing environments. Today, the testing space is defined by a large diversity of applications, requiring a similarly large variety in test methodologies. Companies that take the high ground early, position themselves to benefit over the course of a product‘s lifecycle.

Autonomous cars and e-mobility are trends that are under continuous development. They have rapidly evolved over the past few years and the number of electronic components in today‘s vehicles has exploded. From infotainment (car navigation, center console control), to autonomous driving (image sensors, AI), to vehicle control (driving assistance, tire pressure monitoring, engine control), the present and future potential of this market is phenomenal. The more innovations that are developed, the more markets are created and the greater the demand. Ensuring automotive-grade, zero defect quality is essential in guaranteeing reliability, safety and market success.

Preserving high quality testing

Fortunately for the company, they are ahead of the game. Their wide portfolio gives them the leverage to confidently expand into these rising innovative sectors. The V93000 system is configurable to match device needs, providing DC, digital, analog and RF capabilities on one tester platform. As testing needs change and develop over time, the adaptability of this platform becomes a real benefit as additional modules are added to expand functionality. The RF solution is particularly versatile, as it provides testing for a variety of devices with various levels of complexity, including mobile phones, navigation systems, Wi-Fi, Bluetooth, IoT devices, etc. Up to 32 devices or RF ports can be tested in parallel.

Complementing the platform with the power analog FVI16 card, which is mainly used for automotive, industrial and consumer mobile charging applications, enables exceptionally flexible and transparent high-quality power testing. It utilizes shorter test pulses, which not only saves testing time, but it also prevents the tested device from healing up. Instead of using an analog feedback loop, it features a digital feedback loop design that provides accurate and reliable measurements. It also houses test processor technology with 16 units per card, enabling customers to run tests in parallel, time synchronized and with high throughput. This further decreases testing costs, while improving flexibility and transparency.

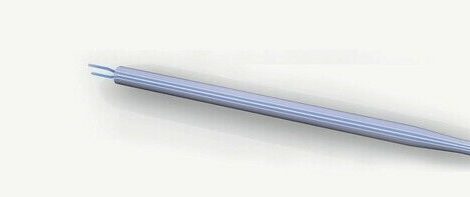

The Wave Scale RF, MX, and MX HR channel cards are used on the same platform for multi-site and in-site testing of RF and mixed-signal devices. Despite these cards having different capabilities, bandwidths and application targets, they are all future-oriented and adaptable to future device test demands. Not only do they extend testing capabilities, but also greatly reduce testing costs.

The T2000 test platform, with air and liquid dual capability, is also available for many different applications, including IoT/module test solutions, automotive and PMIC solutions, etc. This single test platform can cover all segments, including mobile charging technologies, automotive ASSP and battery monitoring. It features high parallelism and multi-site test technology for measuring DUTs (Device Under Test). This significantly drives down costs and slashes the time spent on program development and testing, which ultimately reduces time-to-market. The additional benefits of this technology include overhead reduction, consistent quality and traceability.

The company’s SoC pick-and-place handling systems are also a powerful asset offering unique solutions to handle fine pitch devices and apply precise temperatures. These systems primarily focus on the automotive and consumer markets. The M4841 system has individual thermal accuracy with high reliability, contact force, and throughput. It provides a high level of flexibility by operating across a wide temperature range, with characteristically low jam rates. The M4872 is best known for its active thermal control with a vision alignment option and fast temperature boost. It also has high contact accuracy and accommodates high-power dissipation, which is ideal for optimal yield. This system provides failure detection for applications that demand the highest quality.

As technologies evolve into more complex systems with higher performance capabilities, the future of semiconductor testers will require ongoing development. Advantest will grow along with these and other future innovations, adhering to its strategy of keeping test costs low while delivering high quality, reliable testing solutions.

electronica, Booth A3-632

Zusammenfassung Résumé Zusammenfassung russisch

Das rasante Entwicklungstempo in der Elektronikindustrie verlangt hohe Reaktionsfähigkeit und Anpassungsfähigkeit an die dynamische Landschaft von Innovationen und disruptiven Technologien: Die Lösung ist eine modulare Testplattform.

Le rythme rapide du développement dans l‘industrie de l‘électronique nécessite une grande réactivité et capacité d‘adaptation au paysage dynamique de l‘innovation et des technologies de rupture: la solution est une plate-forme de test modulaire.

Быстрый темп развития электронной промышленности требует способности быстро реагировать и адаптироваться к динамической среде инноваций и прорывных технологий: Решение — модульная платформа для тестирования.