For these users, there is a relatively new technology that can increase dispensing rates for adhesives and other fluids by 20X or more – at rates, for comparison purposes, as fast as 1500 Hz continuously, with up to 2000 Hz maximum burst. This is the Piezo actuated jet dispensing valve that dispenses at approximately twice the speed of the pneumatic jet valve.

Operators often are amazed at the impressive placement precision and small, neat dot sizes generated by a Piezo jet valve, especially considering that a) it is moving so fast, and b), the material is being shot and not physically placed, as would be the case with most dispensing solutions that rely on actual contact with the substrate. Using sophisticated controllers, shot sizes can be achieved as small as 0.5 nanoliter, with outstanding consistency and repeatability. This precision also makes the Piezo jet suitable for some other niche applications where speed is less of a factor, but where operators have a challenging time achieving the desired dispensing of ultra-small dots or ultra-thin lines consistently over time.

Where the speed comes from

Jet valves – both the older pneumatic jet technology and the newer Piezo jet technology – gain a significant speed advantage primarily by eliminating the Z-axis of movement. While the height sensing and repositioning, as well as, the up/down motion that is necessary for contact-based valves such as progressive pump and auger valve technologies – where the needle moves down to touch the substrate to dispense the fluid and then is pulled back up – are considered reasonably fast by most criteria, these account for a high percentage of the required dispensing time. Contactless jet dispensing, by contrast, shoots the material accurately from a fixed location above the substrate, shot after shot. This enables the pneumatic jet valve to reclaim this excess motion time and dispense at speeds some 10X faster than contact-based valves.

However, while the pneumatic jet valve technology leaves the speed enhancement at “only” 1000 %, the Piezo jet valve ups the ante considerably. In these devices, rather than relying upon air pressure, a piezoelectric actuator converts an electrical signal into a highly precise motion that dispenses the material in the desired pattern far faster than a mechanical pneumatic-based solution, which must open, close, and reset, a process that expends about 20 extra milliseconds each time. In this way, speeds up to 2000 % faster than contact-based solutions – 2X faster than pneumatic jet solutions – can be achieved. For speed-sensitive, high-volume, high-throughput applications, the increase in yield can be extraordinary and highly profitable.

Additionally, the ability of this technology to deliver the smallest dots or lines – with micro shots as small as 0.5 nanoliters – is hard to beat as is the accuracy and repeatability of each and every dispense.

Another significant advantage of the Piezo jet technology is its ability to deliver speeds of up to 1500 Hz, even with those operations involved with the production of substrates with irregular heights or those where harder-to-access “nooks and crannies” must be reached. Since the fluid is shot rather than dropped, nozzles can be more readily angled to reach the exact point where material is required. Further, since the nozzle doesn’t need to be dropped down onto the item, products with irregular protrusions, such as a motherboard with high spots, will not be damaged as they might be when using a contact-based valve that must come down close to the substrate. This eliminates a common source of damage, waste and downtime.

How jet valve works

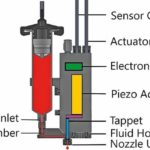

In a Piezo jet valve cycle, the fluid starts inside the valve, held between the tappet (piston) and the nozzle. The electronic piezo crystal oscillates up and down at a high speed, generating kinetic energy that forces the fluid to shoot out under carefully controlled pressure to form a perfect bead of material at the target location.

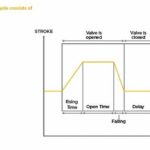

A complete, five step jetting cycle consists of:

- Rising time: Total time for the tappet to move to open position

- Open time: Total time the valve stays opened

- Falling time: Total time for the tappet to move to closed position

- Needle lift: The stroke length, based on the viscosity of the material

- Delay time: Time the valve stays closed, waiting for the next cycle

All of these steps will be repeated over and over again, up to 1500 times per second continuously, with that number an objective basis for comparison with other dispensing methods should be considered. Under real world conditions, the number of drops dispensed per second will be impacted by factors such as desired shot size, the viscosity of the material, and the speed of the horizontal movement of the substrates being assembled. In use, as noted, contactless Piezo jet valves can typically dispense 20X faster than any contact valve.

Ease of use, footprint size and other considerations

When considering upgrading to the power of a Piezo jet valve dispensing system, a vital point to be aware of is that the phrase “jet valve” can refer to both the older pneumatic jet valve as well as the newer Piezo crystal-driven jet valve technology. While both technologies are significantly faster than familiar contact dispensing options, such as the auger valve or progressive cavity pump, the newer Piezo version of the jet valve can deliver up to 2X the speed of the incumbent pneumatic version. Nevertheless, since “jet valve” has been referred as “pneumatic jet valve” for so many years, many people still use the terms interchangeably. Many potential users and even valve manufacturers are relatively unfamiliar with the Piezo jet valve or have not yet had the impressive experience of seeing it in action. In other words, it behooves the buyer to specifically refer to “Piezo” in all discussions to ensure that everyone is on the same page.

Currently, several manufacturers provide Piezo jet valve dispensing solutions, and as to be expected, a variety of design aspects, relating to both the valve itself and the related controller, can differ significantly.

For example, a key issue to consider is the relative ease of identifying the right “recipe”, the combination of parameters to ensure correct placement and the correct amount of material. Piezo valves gain much of their small dot consistency through not only making use of tiny aperture nozzles, but also by providing the flexibility to fine-tune both material pressure and jetting pressure. Once the correct parameters are determined, the valve is extremely accurate and consistent in maintaining them but getting to that point often takes trial and error. Key in reducing the challenge is the provided capabilities of the controller, as well as any assistance that might be available from the manufacturer. As to the latter, some manufacturers might just look at an MSDS and render an opinion. Others will offer some level of hands-on testing of specific material in their labs to ensure efficacy. Further, they might be willing to use the knowledge gained to help fine-tune the parameters in an operation more quickly. It pays to inquire before the sale.

Additionally, the user interface of the controller can make a huge difference in the relative ease of determining the proper parameters and, therefore, the level of potential wasted product or loss of productive uptime during initial product set up. Some Piezo jet dispensing systems require manual tweaking with varying levels of precision; others provide the ability to fine-tune using software that allows the operator to modify the jetting properties for different fluid types and optimize the process for repeatable dispensing. Some include even more full-featured controllers with touch screens and graphic interfaces that optimize usability and make set up faster and more intuitive than in the past. Some manufacturers are raising the bar even further by providing the ability to set parameters as well as monitor and troubleshoot remotely, allowing operators to control their systems from anywhere at any time, around the world, using an app on their devices. These Piezo jet valve models fit into the operation of a sophisticated Industry 4.0-based Smart Factory – or one that is working towards becoming one.

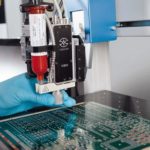

The amount of space that the jet units require also may be of importance to both benchtop users and machine integrators. For the former, sleeker units mean smaller work area demands and more efficient delineation of factory space. For the latter, with the speed and precision benefits of the Piezo jet valve, machine builders are more frequently looking to build one or several units into high end automation application equipment. They are being combined in the cabinet with robots and other complementary devices, in order to deliver best-in-class capabilities to their customers. Towards this end, it may be worth noting the relative size, weight and footprint of the individual brand Piezo jetting dispensing valves that are being considered.

A more esoteric issue is that of all the dispensing valve technologies available on the market, the Piezo jet is not only the most advanced but also the most challenging to manufacture. The tolerances on components such as the nozzle and tappet are extremely tight and crafting them accurately is beyond the capabilities of many parts fabricators. Piezo jet models that cut costs using less complying components will most likely demonstrate issues quickly, including fluids dispensed out of place, inconsistent speeds, cleaning challenges, frequent failures and other problems that negatively impact productivity and quality. As benefits of different models are being weighed, speaking to other users about their experiences should be considered.

Choosing a Piezo jet valve

In addition, there are some limitations to consider. For example, potential users should consider the type of materials to be dispensed. Piezo jet valves can be used with materials demonstrating a very wide range of viscosities – up to two million centipoise or more and including materials as thick as silicone and urethane rubber. However, due to the need to evenly shoot the material, those that have solid particles blended into them, such as solder paste with its ultra-fine metal particles, typically are not the best candidates for jet valve dispensing technology.

Finally, and there’s no way around it, obtaining the superior cutting-edge technology of a Piezo jet valve represents a larger upfront investment than that of contact dispensing systems. However, it can be surprisingly comparable in cost to the older pneumatic jet valve considering how much faster it is. Further, helping significantly defray the lifecycle cost is the fact that the most expensive part of the system, the Piezo assembly, is highly robust and rated at around one billion cycles. Nevertheless, if a process will not benefit from the highest speed dispensing available as well as super-high precision, the investment might not be worth it. However, if a quantum leap in throughput with super accuracy would be valuable, significantly boosting profitability, then a Piezo jet valve might be a highly desirable investment.

Can La, Product Manager, Techcon Systems

Zusammenfassung

Die Auswahl einer automatisierten Dosiertechnologie aus der Vielzahl an Technologien sollte passend zur jeweiligen Anwendung getroffen werden. Der Artikel bespricht die Vorteile der Technologie eines Piezo-Düsenventils.

Résumé

Parmi les nombreuses technologies de dosage automatisé disponibles, il convient d’en choisir une qui corresponde à l’usage prévu. Cet article présente les avantages de la technologie basée sur un clapet à buse piézoélectrique.

Резюме

Выбор подходящей технологии автоматического дозирования из множества доступных на сегодняшний день должен производиться с учетом специфики конкретной области применения. В статье обсуждаются преимущества использования пьезоэлектрических клапанов.

Techcon Systems

10800 Valley View Street

Cypress, CA 90630 USA

Tel.: +1 714–230–2398

E-Mail: oemorders@okinternational.com

Website: www.techcon.com