KIC announced that it will exhibit with SmartRep Germany at SMTconnect, scheduled to take place May 7–9, 2019 in Nuremberg, Germany. The company will demonstrate its Industry 4.0 solution – RPI i4.0, an easy built-in solution for automation, traceability, advanced reflow data collection and sharing for Smart Factory integration.

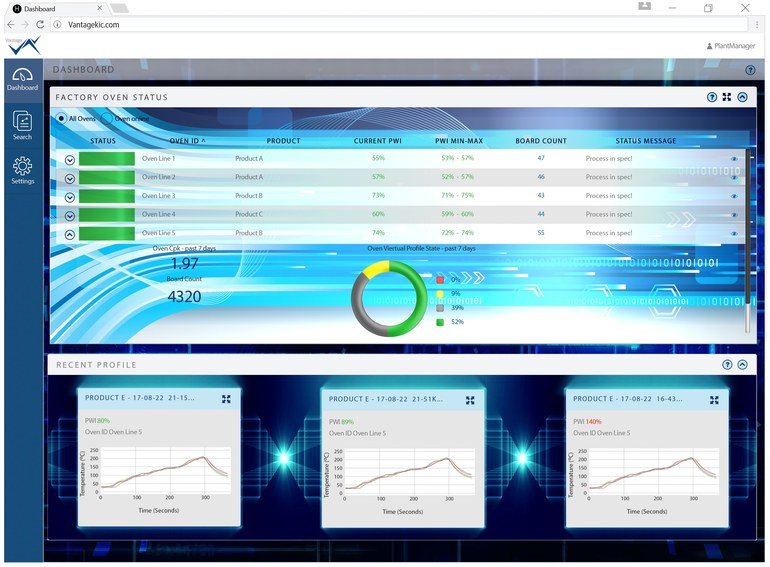

The RPI i4.0 automatically acquires profile data from each PCB soldered in the reflow or curing oven, in real-time. This new ecosystem offers real-time thermal process dashboard and traceability, reduced scrap and rework, fast defect troubleshooting, lower electricity use and more. Advanced data search and communication features save engineers valuable time.

With this solution, all relevant data can connect to the factory MES or a factory data collection system to be easily shared with personnel, and can be accessed from any authorized PC or mobile device. The enhanced level of automation delivers improved line utilization and productivity.

Move toward the future of Smart Factory integration with line connectivity, flexible production, traceability, data analytics, process transparency/control, machine learning and real-time insight.

SMTconnect, Booth 4A-230