The demands placed upon intralogistics systems and processes are becoming ever larger. High-mix, low-volume orders pose a particular challenge as frequent changeovers keep production staff on their toes. The workforce is thinning out as the boomer generation retires, and many vacancies remain unfilled. It is thus more important than ever to deploy the remaining workforce where it is really needed. “When humans are used to transport goods from A to B, storage, transportation and delivery can account for a significant proportion of total production costs,” explains Alfred Pammer, Head of Sales and Marketing at cts.

Intralogistics: often a weak point

The highly networked production chains used in modern electronics production are only as strong as their weakest link. And in many cases, this is intralogistics. Only those who automate standard tasks in this area can make optimum use of employees and expensive production equipment to achieve maximum ROI. Implementation of a new logistics concept requires a system integrator who, together with the customer, carries the project through from A to Z: from initial meeting to turnkey handover.

The disrupted supply chains seen in recent years have caused production planning to become a risky undertaking if sufficient storage and buffer capacities are not planned and accommodated for. Moreover, no two electronics production facilities are the same. The extent to which it makes sense to replace human labour with machines is something that must be assessed on a case-by-case basis. Implementation, too, must be tailored to suit a customer’s individual needs.

Taking all this into account, we can conclude that any new intralogistics automation concept in the electronics manufacturing sector must meet the following requirements:

- It must have a modular structure and be easily scalable.

- It must integrate technology from different manufacturers.

- It must be customizable.

- It must take into account the space available

in the production facilities.

It is rarely worthwhile for electronics manufacturers to plan and implement automation in intralogistics themselves. As there is a wide range of hardware and software on offer, comprehensive know-how is required to make the right purchasing decision. Ensuring system-to-system networking is even more difficult. “This requires a great deal of experience,” Pammer points out, ”because the devil is in the detail. There are highly complex compatibility problems to solve, but also very trivial things to consider – not every industrial floor is suitable for heavy storage systems or autonomous vehicles, for example. There is also usually a problem with space: storage space is both scarce and expensive and must, therefore, be optimally utilized.”

One system integrator,

one point of contact

cts says its ’Smart Intralogistics for the Smart Factory’ concept, developed on the basis of numerous successfully implemented projects, provides the solution to these challenges. “We provide electronics manufacturers with a stringent, automated intralogistics infrastructure from a single source,” assures Pammer. “With our Smart Logistics concept, we provide collection, storage, buffering, transport and quality assurance systems for the Smart Factory, as well as comprehensive software integration. Everything comes from a single source which means we take care of everything, from planning, installation and commissioning to ongoing maintenance. And if the floor is too uneven for driverless transport systems, we also arrange the necessary construction work.

”The customer thus obtains a solution from just one system partner and has a single point of contact for both planning and implementation. They are free to decide at any time which automation step they want to implement and which solutions they want to use. Thanks to the individual configuration and modular structure, the concept is also very effective for small and medium-sized companies and usually pays for itself surprisingly quickly.”

’Everything from a single source’ does not, however, mean that all hardware and software components used come from one and the same manufacturer,” emphasizes Pammer. ”Rather, the challenge is to ’select the best of each and combine them to create a customized system solution that precisely meets the customer’s needs.”

The solution ultimately handed over to the client is by no means fixed. Each project is unique. “Recent years, in particular, have shown how quickly conditions can change,” says Pammer, “and cts can react just as quickly. Everything is neatly documented so that we can expand or modify the Smart Factory solution quickly and easily. The customer can be sure that the new system will work just as smoothly as the previous one. We only leave when everything is up and running and he has given his OK.”

Manufacturer-neutral advice

and conception

When putting together its modular solutions, cts draws on a large pool of mature systems from a wide range of manufacturers. Internal material flow begins with the recording of delivered materials. This is done by the Gigaflex FlyScan WE 12P scanner. With a large reading field of up to 540mm x 400mm, the system registers deliveries based on the container ID with just one scan. The packs are pulled under the camera using the FlyScan process. The system works without adjustments or teach-ins and can read 1D, 2D, PDF or special codes.

An inline X-ray counter ensures fast, precise and non-contact component detection. The most suitable brand is selected together with the customer. Almost all devices available on the market use AI-based algorithms to provide the planning system with up-to-date data on component stock.

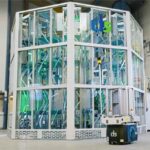

The storage and retrieval of PCBs, SMT-reels or consumables is automated throughout thanks to the cts Smart Warehouse storage system. It is available in sizes starting from a footprint of 9m x 4.5m and a height of 4.3m. The warehouse structure can be customized. Shelves can store between 400 and 1100 PCB magazines. Alternatively, KLT boxes, trays or other workpiece carriers can also be stored. Individual adjustments in length and height are also possible to optimise use of the available space. The company also offers a more compact version of the modular storage system in the form of an octagon. With a footprint of 4.2m x 4.2m or 4.8m x 4.8m, the Mini Smart Warehouse is extremely space-efficient and can hold 80 to 280 PCB magazines. With the appropriate room height, a higher capacity can be achieved. Using both systems, it is also possible to connect across floors.

Transfer stations which are available from cts in various designs, ensure buffering directly on the production line. These include gravity systems on one or more levels as well as motor-driven versions which come with the option of sensors.

The Gigaflex Storage Center offers a completely new material, logistics and picking system for all SMT component reels across electronics production. It offers an enormous storage volume in a very small space. More than 50,000 7” reels can be stored on a floor area of approx. 50m2. It also offers full transparency and traceability. The Storage Center consists of a complete climate zone with a relative humidity of 5%rH to enable the storage of critical MSL reels and thus comprises a fully integrated MSL material handling system. In addition to this, separate zones for the re-drying process can be integrated without additional air conditioning of the total volume.

Autonomous transport systems (AMR/AIV) are much more efficient and cost-effective than employees when it comes to transporting the required materials into the warehouse or to the line. The cts portfolio comprises a wide variety of designs which can be used immediately and requiring no structural measures, such as induction loops, for orientation. Fleet operation can include up to 100 vehicles. The transport infrastructure can be rescaled at any time and is always configured centrally.

To complement the transport system, the company also offers the sloXis middleware, which can be used to control and manage heterogeneous AMR fleets (which comprise systems from different manufacturers). The modular solution supports native interfaces and the integration of open VDA5050 fleet managers. Operation is web-based and, thanks to its modular structure, the software can be expanded and adapted quickly and easily – catering for everything from the automatic generation of transport orders to role-based configurations, tracking solutions and extensions to communication options, through to door and elevator control. True to the open Industry 4.0 concept, the middleware also supports modern interfaces such as REST and MQTT.

SMTconnect, Stand 4.213

Zusammenfassung Résumé Резюме

Intra- und Produktionslogistik ist eine zentrale Aufgabe, um in Zukunft wirtschaftlich arbeiten und weiter konkurrenzfähig produzieren zu können, wobei Mensch und Maschine in der digitalen Fabrik verbunden sind und Material- und Warenflüsse optimiert werden.

Reliant l’humain et la machine dans l’usine numérique et optimisant les flux de matériaux et de marchandises, les tâches de logistique interne et logistique de production jouent un rôle central pour garantir la rentabilité du travail et une production toujours aussi concurrentielle à l’avenir.

Внутренняя и производственная логистика – это главная задача, которая позволит в будущем достичь рентабельности в работе и продолжать производить конкурентоспособную продукцию, что предполагает взаимосвязь человека и машины на цифровой фабрике, а также оптимизацию потоков материалов и товаров.