PVA, a global expert in dispensing, coating and custom automation, will exhibit at SMTconnect, scheduled to take place May 7–9, 2019 at the NurnbergMesse GmbH in Nuremberg, Germany. Company representatives will showcase the Delta 8 selective coating/dispensing system and Delta 6 robotic conformal coating/dispensing system.

The Delta 6 is ideal for selective coating, potting, bead, and meter-mix dispensing applications. It features a robust overhead three-axis motion platform suitable for inline or batch operations. It has been designed with a slimmer footprint, improved structural and gantry rigidity for robustness, and easier access, and will be configured for SMT underfill with the JDX jetting valve and SVX auger valve.

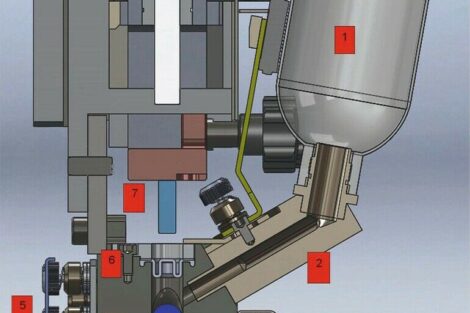

The JDX jet dispense valve is an extremely fast, non-contact jet valve that precisely dispenses viscosities up to 400,000 cps, while its unique diaphragm design saves time and money. The SVX auger valve is ideal for dispensing all medium to high viscosity pastes, epoxies, and abrasive compounds in dot and bead patterns and can dispense dots as small as 0.005 “ in diameter.

The Delta 8 will be shown with the patented 4th axis for conformal coating. The optional servo-controlled four-axis motion features valve tilt and rotation. Designed for multiple applications, this system is flexible beyond conformal coating as it can easily be configured for custom assembly operations, such as part pick & place, screw driving, scan & label, press, etc.

Improved structural and gantry rigidity have been added for robustness and easier access. Delta 8 has a maximum acceleration of 0.5 g, and a footprint 1046 mm x 1270 mm x 2350.9 mm (41.18 “ x 50.0 “ x 92.56 “).

Experts will be available to answer questions about coating and dispensing, as well as other application solutions in the company’s line-up, such as coating inspection, optical bonding and curing ovens.

SMTconnect, Booth 4–460