Yamaha Robotics SMT Section has revealed performance-boosting upgrades for the YRi-V 3D AOI system, including faster board handling, multi-component alignment checking, and enhanced LED coplanarity measurement.

The new stopperless transfer system brakes and stabilises each board electronically after entering the machine, cutting the time to position the assembly ready for inspection. The cumulative time saving accelerates the completion of every batch and significantly increases overall productivity.

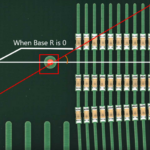

The new multi-component alignment check simplifies programming the system to measure the distances between arrayed parts such as LED emitters in automotive or general lighting. When building automotive headlamps, users can leverage the captured AOI data to individually optimise the placement of beam-focusing lenses for maximum lighting performance. The alignment check can be used to verify the spacings between many other types of components, such as Hall sensors for precision motion control.

The multi-component checking feature helps setup the YRi-V to measure alignment and spacing, for applying corrections or recording positions

The upgraded height measurement system, using a blue laser, ensures accurate and repeatable height assessment for components that are difficult to capture with standard equipment, such as transparent LED packages. Now offering superior capabilities, the YRi-V helps lighting manufacturers ensure greater product reliability with superior optical performance and visual appearance. In addition, the YRi-V can be now equipped with a 25-megapixel top-camera system, which significantly expands the inspection area that can be imaged at one time.

“Our latest upgrades further extend the YRi-V’s ability to maximise quality assurance, addressing cutting-edge automotive, industrial, and consumer applications,” said Daisuke Yoshihara, General Sales Manager. “Our customers benefit from ongoing enhancements to their YRi-V systems as we continue to make new features available enabled by advancements such as new machine-vision technologies, motion control, and AI.”