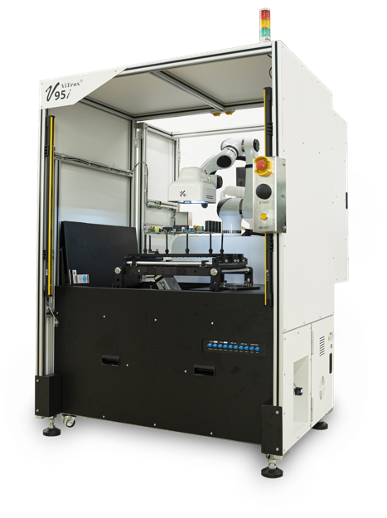

Vitrox, has announced the introduction of the V95i Advanced Robotic Vision (ARV) Solution Rotator. The company says the rotator greatly enhances the inspection efficiency of its V9i ARV (advanced robotic vision) system to improve production efficiency. The new solution is designed to fulfill final assembly inspection requirements in box build and PCBA products, by being an additional hardware option to the ARV. It enables auto-conversion between inspections of PCBAs and Box Builds within a system. The rotator enables 5-sided inspection for both complete or in-process box build assemblies, hence increasing the coverage of inspection as it helps ARV to reach the areas beyond the limitations of the robotic arm – which in turn further ensures product quality.

The new rotator is fully integrated within the V9i ARV system. “Our ARV technologies began with the all-in-one lighting design, which includes motorized vari-angle UV and RGBW lighting for conformal coating inspection and final inspection. The V9i ARV is attached to a 6-axis collaborative robot (COBOT), allowing for multi-angle inspection of printed circuit boards (PCBs) up to 510mm x 510mm in size. Moreover, it has been designed with an advanced CAD-less smart learning capability that uses both machine learning and rule-based algorithms, allowing for quick recipe setup and comprehensive inspection coverage that includes foreign object detection as well as cosmetic defects on PCB surfaces.”