This year‘s IPC Apex Expo 2021 will be held virtually from March 8 –12, 2021 due to the pandemic. The online event platform is nevertheless designed to meet visitors‘ expectations and promises the usual showcases of the latest technologies as well as exchanges with the experts in more than 100 technical conferences, live product demonstrations and one-to-one meetings. Viscom Inc. will also be there, using the digital platform to present several innovations for the first time. They are introducing new systems to the market in all solution areas, such as 3D SPI, 3D AOI, 3D AXI, 3D bond and CCI, which offer even faster, versatile and, above all, highly precise inspection of electronic assemblies, wire bonds and protective coatings. As a highlight, the system generation iX7059 celebrates its premiere and is first shown in a live demo.

Automatic X-ray inspection

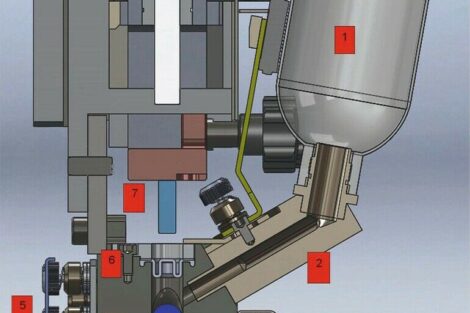

Unlimited possibilities and the most stringent quality assurance are offered by the inline X-ray system iX7059 PCB inspection XL for high-end electronics production. At the heart of the 3D AXI system is CT-based 3D X-ray technology which provides high-speed and high-quality imaging. The combination of a powerful microfocus X-ray tube, flat panel detector and innovative dynamic image acquisition produces sharpened tomographic results at the highest level. Comprehensive inspection of hidden solder joints, complex and thick printed circuit boards which are fitted with THTs, BGAs, CSPs, QFPs, SSOPs, chips and LED is guaranteed. The fully automatic X-ray system is specially designed for the inline comprehensive inspection of very long printed circuit boards up to 1,600 mm in length and 15 kg in weight.

The iX7059 heavy duty inspection X-ray system is also part of the company’s iX7059 series for fast, fully automated inline X-ray inspection. Viscom has developed a special transport system for the handling of workpiece carriers and soldering frames to ensure that heavy and encased assemblies can be transported and inspected in optimized cycle times. This special system can transport assemblies with dimensions of up to 500 mm x 500 mm and a weight of up to 40 kg. As a result, fully automated X-ray inspection is gaining a foothold in new sectors such as electric vehicles, network infrastructure for the telecommunications 5G standard and in the area of renewable energies.

Solder paste inspection

To prevent errors from the very beginning of the SMT process, the use of a 3D SPI system in the SMT line is indispensable. The company’s S3088 ultra chrome system provides outstanding 3D solder paste inspection by combining compact design, fastest handling and best inspection quality for high-throughput, defect-free electronics manufacturing. A newly developed sensor system based on advanced XM camera technology is used. The combination of 10 μm resolution and four angled views provides shadow-free images to reliably detect the smallest inspection areas. At the same time, the uniquely large inspection area also covers heights up to 4 mm for very high paste deposits. It is also available as a dual lane system. Intelligent networking of 3D SPI, 3D AOI, 3D AXI and verification station ensures maximum quality and process efficiency.

Wire bond inspection

Viscom is also introducing a 3D wire bond inspection system which provides additional height information. Bond wires with a diameter of less than 25 µm can be measured in three dimensions – the actual height of the loops is an important test property in addition to the shape. Also the standard algorithms of wire bond inspection allow an excellent safeguarding of wire bonded circuits against defects.

Conformal coating inspection

Viscom‘s S3088 CCI inspection system ensures high-precision conformal coating inspection of printed circuit boards. The inspection process uses white light and special UV LEDs which reliably reveal defects in UV-sensitive conformal coating. Optimal inspection coverage is ensured by means of one orthogonal camera in combination with four, or optional eight, angled view cameras, which allow for accurate inspection of component sides and gaps between pins. The system quickly and reliably detects typical defects such as cracks, coating voids, smearing and splashing. With the 3D spot measurement option, the system also provides layer thickness measurement. The S3088 CCI comes with an unmatched upper transport clearance of 105 mm. Thus, it provides even more flexibility during final inspection of fully assembled components wherever electronic components need to be protected against damaging environmental influences.

Viscom AG

Carl-Buderus-Str. 9–15

D-30455 Hannover Germany

Tel.: +49 511 94996–0

E-Mail: info@viscom.de

Website: www.viscom.com