For decades, vapor degreasing was the cleaning technology of choice in the precision and finishing industries. This came to an end in the 1990s, when the ozone depletion issue forced the phase-out of the most popular vapor degreasing solvents, and water-based systems filled some of the void. With modern closed-loop equipment and newly formulated solvents, vapor degreasing is a safe, cost-effective and environmentally acceptable cleaning method.

John Hoffman and Tom Tattersall, MicroCare Corp.

Today, a great deal of precision cleaning is performed using aqueous technology, but the tide is turning once more with several contributors leading to its demise. Water, for example, is an issue for certain regions with water shortages, extreme drought conditions and even water rationing. Aqueous cleaners also require a considerable amount of electricity when heating the water, additional equipment for preparing and afterwards treating this water, these are requirements in order to clean satisfactorily. And then there is the requirements in large quantity of energy required to dry the parts. This can be a real problem, especially as companies are under increasing pressure to reduce the amount of energy they use. In addition, aqueous cleaning systems tend to have large footprints, require significant capital investment, are maintenance intensive, and usually need processed water and after the procedure a waste water treatment.

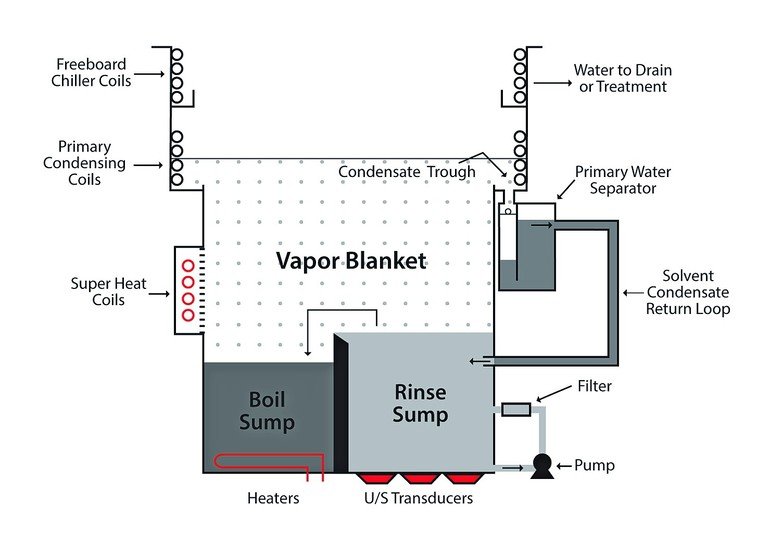

Most young engineers feel these constraints are the only option, but there is another alternative and one straight from the history books. If you are willing to go “back to the future,” it is time to revisit vapor degreasing. The concept behind vapor degreasing is very simple. Look at the design of a modern, efficient, two-sump degreaser. A vapor degreaser boils a solvent producing a vapor, the cold primary condensing coils contain this vapor by cooling back into a liquid, and pure condensed solvent is collected for continuous use.

A vapor degreaser therefore is not only a cleaning system but also a solvent recovery system that continuously recycles and purifies the solvent for reuse. Unlike aqueous systems, the cost savings and environmental benefits of recycling are inherent features of a well-designed vapor degreaser.

To begin with cleaning, the solvent is placed in the “boil” sump (lower left chamber in the figure) where the solvent is heated to its boiling point, usually 100–170 °F, depending upon the solvent. The heat can be provided with electric heating elements, hot water coils, steam coils or from a heat pump refrigeration unit.

Once boiling, the solvent produces a clear, dense vapor that rises through the machine, displacing the air inside the degreaser to form a vapor blanket. The vapor blanket will continue to rise until it reaches the lower set of refrigerated coils (the primary condenser coils) that surround the interior sidewalls of the degreaser. These coils cool the vapor and condense the solvent back into its liquid state.

This condensed solvent continuously drips off the primary cooling coils into a condensate trough that is under the coils. It is then routed through a water separator, decanting any water that may have condensed on the coils and removing the water from the solvent. It is important, in a properly designed degreaser, that the coil cooling capacity must equal the energy input used to boil the solvent in order to establish the proper heat balance.

Vapour degreasing concept

At this point, the distilled solvent is directed back into the rinse sump from the water separator (lower right chamber). Since the rinse sump already is filled with clean solvent, the addition of more clean, newly distilled solvent will cause the sump to overflow into the boil sump, completing the distillation cycle.

Vapour degreasing is the only cleaning system that automatically regenerates the cleaning fluid as part of the basic system. The addition of this fresh, pure solvent maintains a consistently clean rinse sump and also allows contamination and particulate to be washed back into the boil sump. At the proper time, contamination in the boil sump can be concentrated for disposal. Aqueous cleaner systems, on the other hand, typically dilute contamination making disposal or recycling more difficult.

As you can now see, the term vapor degreasing is a kind of misnomer. In some cases, people try to clean strictly in the solvent vapor blanket, with the solvent vapor condensing on to the parts and thereby rinsing away contamination. But in most instances, faster and more reliable cleaning is found when the parts are immersed directly into the solvent inside the vapor degreaser. When immersed, the liquid will completely surround the part, entering any crevices, maximizing solvent contact and ultimately cleanliness.

It is particularly noteworthy that a water-cleaning system will consume considerably more energy in heating the cleaning mixture and drying the parts spot free than a vapor degreaser of comparable capacity. The higher energy consumption is unavoidable because water has a much higher specific heat and a much higher latent heat of vaporisation than any of the commonly used vapor degreasing solvent. It takes approximately 1000 BTUs to boil a gallon of solvent, but 8,340 BTUs to boil a gallon of water. (The British Thermal Unit BTU is not part of the standardized SI system, it defines the heath energy needed to heat-up a British Pound of water by 1 °F. 1000 BTU/h is about 293 Wh.)

This fundamental characteristics of water explain why aqueous systems are so energy-intensive. As a rule of thumb, aqueous cleaners will consume approximately eight times the energy versus a properly designed vapor degreaser to clean the same number of parts.

Equipment considerations

Numerous options are available which make this process even simpler, cleaner and faster. The rinse sump is usually equipped with with a circulating filtration system to remove insoluble particulate contamination. Another common option is for the rinse sump to be fitted with ultrasonic transducers to enhance cleaning. The use of automated hoists not only frees up the staff from lifting parts in and out of the system, but ensures a proper cleaning cycle and part movement. Ultimately, automation leads to reduced solvent consumption, reduced labor costs and more consistent cleaning.

Another important feature of modern vapor degreasers is a second set of cooling coils, located above the primary condensing coils. These are called freeboard chiller coils (top left in the figure), and they are always colder than the primary condensing coils. The purpose of these coils is to cool and dehumidify the air above the vapor blanket in order to minimize solvent diffusion from the saturated vapor blanket into the air. Cooling and dehumidifying the air above the vapor blanket helps to minimize solvent losses and consumption. In addition, since the freeboard chillers dehumidify the air above the vapor blanket, minimal humidity will be condensed on the primary condensing coils, which helps maintain solvent integrity.

Cost-effective cleaning with vapor degreasing

The freeboard chiller coils are not designed to contain the solvent vapor blanket in the degreaser. That is the job of the primary condensing coils. If the vapor blanket ever rises above the primary condensing coils into the area of the freeboard chiller coils, than there is something wrong with the primary condensing coils and a service technician from the machine supplier needs to be consulted.

Another degreasing option called super-heat is available from some manufacturers to ensure parts are completely dry before removing them from the vapor blanket. The super-heat coils (left side in figure) force the temperature of the vapor blanket above the “normal” boiling point of the solvent. Clean parts that dwell in the super-heated vapor blanket increase in temperature rapidly, eventually exceeding the boiling point of the solvent. Once the temperature moves higher than the boiling point of the solvent, all of the solvent on the parts will flash off. This means the parts are completely dry prior to being removed from vapor blanket. This process minimizes solvent drag-out and lowers operating costs.

There are numerous world-wide manufacturers of vapor degreasers. This equipment type ranges from manually operated units, holding a few gallons of liquid, to fully automated systems with capacities of many thousands of gallons. Depending on the cleaning application and unique process requirements, the technology exists to easily handle the largest parts and highest volumes. These large machines, when properly designed, operated and maintained are extremely efficient with minimal solvent consumption. By comparison, no other method out-performs the cleaning efficiency of a modern vapor degreaser.

Comparing costs

Despite the historically proven performance advantages of a vapor degreaser, engineers are always concerned about operating costs. After all, water is basically “free”, while a cost is attached to safe, environmentally acceptable solvents. Can vapor degreasers truly cost less to run than water-based cleaning systems?

The answer is unequivocally yes. The best way to evaluate the operating costs of different types of cleaning systems is to compare them on a cost-per-part-cleaned basis. This approach provides a true apples-to-apples comparison that can reveal the hidden costs of water-based cleaning.

Firstly, the acquisition and installation costs are tabulated. Included among these are direct capital costs of the cleaning system (the hardware itself, plus the support systems, waste water treatment systems, and so on), as well as the indirect capital costs (floor space, upgrades to the facility’s electrical system, plumbing costs, etc.). The next step is to estimate the direct operating costs for both systems. This includes the solvent and water costs (filtered, deionized, reverse osmosis RO, etc.), energy costs, labor costs, waste disposal costs, inventory costs that change due to faster or slower cleaning cycles, and any other direct expense that touches the cleaning system. And we also need to take into account the personnel needed to operate and maintain the cleaning equipment. Vapour degreasers require minimal maintenance while aqueous systems are considerably more complex to operate, are maintenance intensive, require waste water processing systems and are time-consuming just to keep them operational. Water cleaning is basically a complicated chemistry set where the water, surfactants and detergents chemically react with the contamination. In contrast, vapor degreasers are simple thermo-mechanical systems and the solvents simply dissolve the contamination away.

On the other hand, the solvent cost itself has to be considered when looking at a vapor degreaser. While the solvent selection process is beyond the scope of this article, evaluating the cost of the solvent is simple. The proper and sensible way to estimate solvent costs is not to compare the cost-per-gallon which would be misleading, but to compare the cost-per-part-cleaned.

For example, a modern vapor degreaser will use approximately 0.028 kg of solvent/hour/square feet of solvent/air interface when in use. A typical 38 liter degreaser has about 2.5 feet of solvent/air interface, so it will lose about 0.56 kg of solvent in an 8-hour work day or shift. When these costs are tabulated and then divided by the total number of parts cleaned by the system, the true cost of cleaning solution for each one becomes apparent.

Conclusion

In the past, vapor degreasing has proven to be the most consistent and head-ache free cleaning process in the manufacturing area. But now, vapour degreasing has come full cycle again, and engineers are realizing that it is a safe, economical and environmentally-acceptable method. Energy consumption issues, high costs and demanding environmental concerns associated with aqueous cleaning are generating an increased interest in the vapor degreasing process. If an aqueous cleaning system is reaching the end of its life cycle, now is the time to explore vapor degreasing as an appropriate alternative.

However, engineers have to be smart about their cleaning processes. In order to obtain the desired results in the most economical and environmentally acceptable manner, it is an imperative that the degreaser system be properly configured, operated and maintained. In addition to the degreaser selection, the proper solvent choice requires careful analysis and that decision depends on the contamination being removed and the final cleanliness criteria. When analyzing the application, always define the soils first, then select the chemistry that removes those soils, and lastly select the equipment that uses the chosen solvent properly. Vapour degreasing is being revitalized. Now, where quality, reliability and energy-efficiency are paramount, the old and also new process of vapor degreasing truly is the modern, planet-friendly and cost-effective cleaning process for many tasks.

Share: