Solderstar, a leader in temperature profiling equipment for soldering processes, will showcase its latest innovation, the Reflow Shuttle with O2 measurement module, at the upcoming SMTconnect exhibition in Nuremberg, Germany.

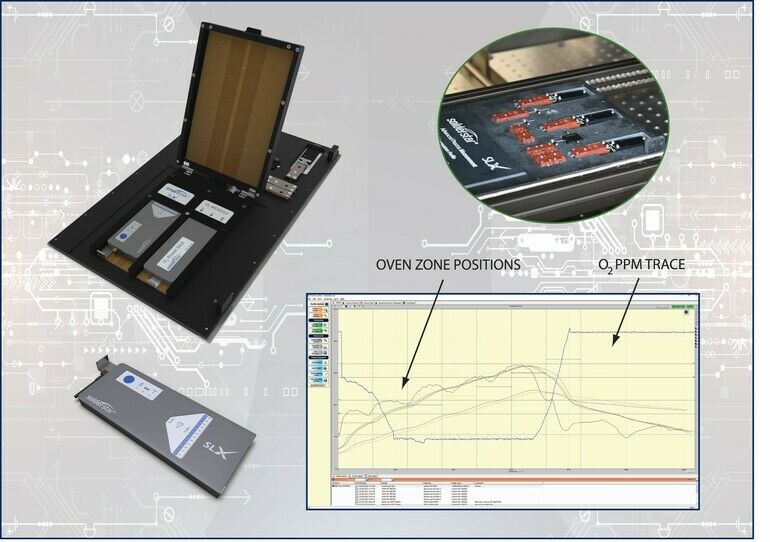

The company says the Reflow Shuttle O2 represents a significant leap forward in reflow soldering technology, offering manufacturers a new tool for achieving precision and control in their soldering processes. It consolidates real-time oxygen (O2) measurement, vibration levels, vacuum reading, temperature profiles, and conveyor speed onto a single robust platform.

“With the Reflow Shuttle O2, we are providing manufacturers with the tools they need to make informed decisions and optimise their reflow soldering processes,” Mark Stansfield, CEO of Solderstar, said. “By offering detailed insights into all critical parameters, we‘re enabling our customers to enhance quality and efficiency in their soldering operations like never before.”

The Reflow Shuttle O2‘s zone-by-zone analysis of oxygen levels throughout the reflow process enables manufacturers to precisely monitor oxygen content and detect nitrogen leaks, allowing for immediate adjustments to optimise nitrogen consumption and ensure process quality is maintained.

One of the key features is its simple integration into existing reflow ovens, eliminating downtime during verification. Its user-friendly interface enables easy data collection initiation, facilitating rapid adjustments if irregularities are detected. The tool‘s design ensures uninterrupted verification across multiple production lines, enhancing overall manufacturing efficiency.

SMTconnect 2024, Stand 4.314