Plasmatreat will attend electronica and SEMICON Europa for the first time in 2024. The company will be exhibiting in hall C5 at booth 169. The company will showcase its Openair-Plasma technology, which the company says is set to revolutionize the electronics manufacturing industry in the field of power modules and semiconductor manufacturing. Together with partner KRÜSS GmbH, specialist for contact angle measurement devices and other tools in the field of surface analysis, the company will display various plasma systems including the REDOX-Tool for flux free and inline oxide reduction following by PlasmaPlus nanocoating to prevent EMC delamination in molding processes.

About plasma technology

Plasma technology is an advanced method that utilizes ionized gas to modify the surface properties of materials, e.g. metals, plastics or glass. With plasma manufacturers can achieve superior cleaning, activation, coating and reduction of surfaces without the need for harsh chemicals or solvents. This innovative approach not only enhances adhesion but also improves the overall performance and durability of electronic components in pre- and post-processes.

Long-lasting power modules

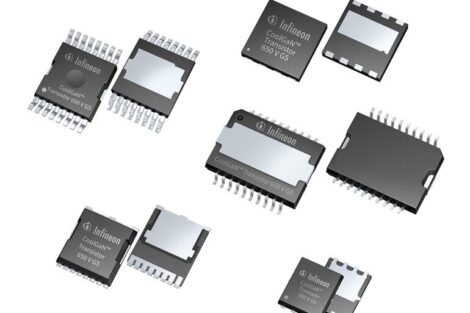

One of the key challenges in power module manufacturing is the effective removal of oxide layers on metal surfaces. Openair-Plasma technology solves this issue: inline, during the production process, a plasma system, the REDOX-Tool, is able to remove the oxide layer without the use of fluxes. Following this process, a nano-thin, environmentally friendly adhesion promoter layer is applied through PlasmaPlus coating technology. This layer plays a crucial role in preventing EMC delamination during subsequent molding processes. The result is a robust and high-performance power module with an impressive 100% yield.

The tool for automated oxide reduction will be showcase at electronica and SEMICON Europa as well as the PlasmaPlus plasma system for coating power modules before the molding process. Visitors can see this automated, dual-lane process with potential-free plasma treatment live in hall C5 at booth 169. Other benefits and aspects of the particular application process can be discussed with Plasmatreat‘s plasma experts on site.

Activating and cleaning semiconductors and PCBs

With the semiconductor plasma system, Plasmatreat is showing a standardized production cell for inline surface treatment in the semiconductor industry that can be seamlessly integrated into existing production lines. The system uses Openair-Plasma to effectively remove organic and silicon-based contaminants as well as electrostatically charged dust. It is used prior to key process steps such as wire bonding, die bonding, thermal compress bonding, underfill and PCB assembly. In addition, PlasmaPlus enables the creation of customized coatings that provide maximum protection and prevent problems such as epoxy leakage, reoxidation or corrosion.

According to Nico Coenen, Global Director Electronics Market at Plasmatreat, the pre-treatment of highly sensitive products with potential-free Openair-Plasma makes a decisive contribution to higher product quality, cost efficiency, increased process reliability and environmental friendliness. This plasma technology therefore offers significant advantages for semiconductors and printed circuit boards (PCBs) and creates optimum conditions for various manufacturing processes.

Integrated system in Plasma Treatment Unit

Plasmatreat will be exhibiting together with its partner Krüss on booth 169 in hall C5. The company will be demonstrating the integration of the Krüss Ayriis portable contact angle measuring system into a PTU (Plasma Treatment Unit) – a fully automated plasma production cell. The focus will be on demonstrating how plasma surface treatments can increase the wettability of materials, thus improving the adhesion of adhesives, for example, and how the contact angle on surfaces can be measured. The integration of the Ayriis analysis tool from Krüss enables robotic, automated, in-line contact angle measurement. This advanced technology enables seamless quality assurance in the production line through fast and accurate measurements. This not only increases efficiency, but also ensures that joints and end products meet the highest quality standards.