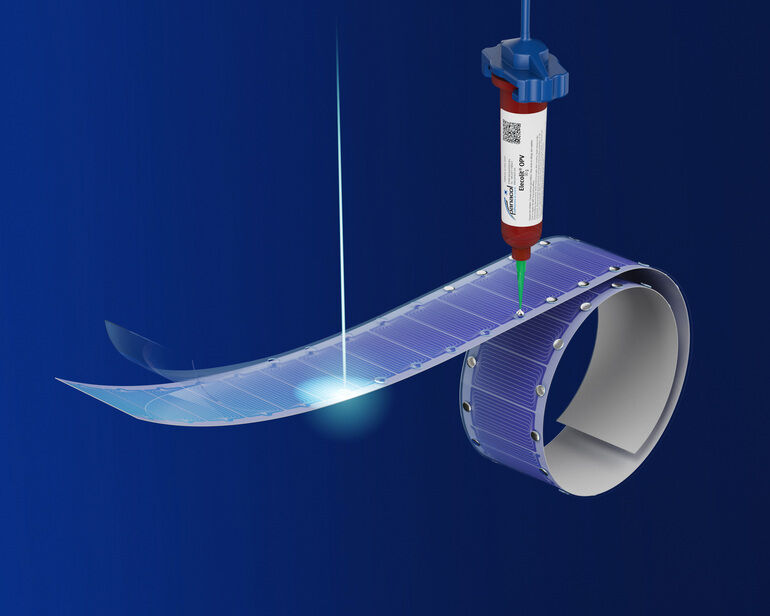

Perovskite-based and organic photovoltaic (OPV) cells represent a promising pathway to renewable energy generation due to their potential for lightweight, flexible, and potentially cost-effective solar power generation. Panacol complements new OPV technologies with Elecolit 3648, a newly developed conductive adhesive. The product addresses one of the critical challenges in the commercialization and long-term reliability of organic solar cells: creating long-lasting, flexible electrical connections that create and maintain reliable electrical circuits.

Electronic components are typically connected by soldering. But solder materials are rigid and inflexible, and soldering temperatures are often too high for potentially heat-sensitive photoactive materials. Conventional conductive adhesives cure at lower temperatures but can still be brittle and inflexible.

The new product is a very flexible, conductive adhesive. As it adheres well to plastics, including PI, PC, PVC, ABS, and FR4, Elecolit® 3648 is the perfect choice for an efficient attachment of wire leads and components to create flexible connections.

The adhesive can be cured at relatively low temperatures of 80°C within a few minutes. At higher temperatures, it can be hardened within seconds as a “snap cure” adhesive. As a one-component system, the new adhesive simplifies manufacturing processes by eliminating the need for mixing and therefore ensures a consistent application. It is easy to process and can be dispensed by conventional dispensing equipment, by jetting or screen printing.

Elecolit 3648 can efficiently secure flexible resistors and create flexible electrical connections in solar cells to lead the generated electricity from the conductive tracks to the end device. This adhesive is also effective in touch sensors or wearable devices where flexibility is a desired property.

These features make this the perfect solution to replace solder joints in applications subjected to vibration, oscillation or rapid temperature changes. This can includes all configurations of flexible electronics, and specifically OPV. As the adhesive maintains its integrity after repeated bending and stretching, it can help to facilitate the development of new devices that withstand challenging operating conditions without losing performance.