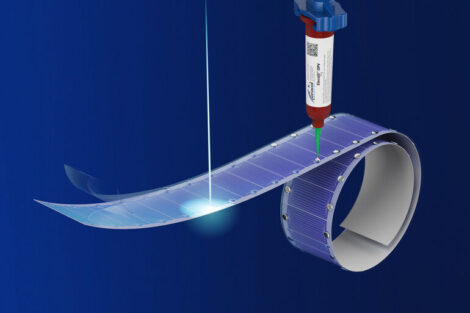

Manufacturing of fluxing agents Emil Otto has expanded its metal chemistry product portfolio for soft soldering with the new ZINNIN Green soldering and tinning pastes. The sustainable soldering and tinning pastes do not require zinc chloride, are therefore not subject to hazard labelling and can be used for soft soldering and tinning. They are particularly suitable for processing steel, brass and copper alloys. They can also be used in the electronics industry.

“During soft soldering, metals are joined together using a solder at process temperatures below 450°C. To ensure that these joints are as stable and durable as possible, the surfaces of the metals to be soldered must be as clean as possible and free of oxides. The formation of oxides during the soldering process should also be avoided. In order to achieve this, we have developed a wide variety of products such as flux concentrates, ready-to-use fluxes, soldering lotions, oils, pastes and greases. This includes the newly introduced soldering and tinning pastes,” explains Markus Gessner, Head of Marketing and Sales at Emil Otto GmbH. The pastes are used in the metalworking industry as well as in electronics production and is also suitable for tinning printed circuit boards. They are available in three variants with different alloys: ZINNIN Green I with the alloy Sn100, ZINNIN Green II with the alloy Sn96.5 Ag3.0 Cu0.5 (SAC305) and ZINNIN Green III with the alloy Sn97Cu3.

Before use, the paste must be stirred until the green colour of the usage indicator changes to metallic silver grey. “This is absolutely essential to return the paste to a usable state. Stirring can be done with a stainless steel or wooden spatula,” continues Gessner. The paste is then applied to the parts to be treated using a brush or similar. In the case of overlapping parts or grooved pipe connections, the overlaps should also be lightly coated with the paste. “Due to the excellent activity of the contained flux, the new pastes spreads very well on the surfaces of the workpieces and penetrates perfectly into soldering gaps,” says Gessner. If flux residues are formed after the soldering process, they can be removed with deionized water.

ZINNIN Green pastes are suitable for both industrial and craft applications and is available in various packaging sizes.