Inspection technology provider Mirtec will showcase its INTELLI-PRO AI Based Smart Factory Automation Solution and GENSYS-PIN Automotive Pin Inspection System at the 2021 Productronica exhibition in Hall A2, Stand 461.

“It’s been a while since the industry started to integrate Artificial Intelligence into their products to realize the Smart Factory,” said Holger Hansmann, President of Mirtec Germany. “As one of the pioneers for AI development in this field, Mirtec recently released its comprehensive AI based Smart Factory Automation solution ‘INTELLI-PRO’. This technologically-advanced software and algorithm package is specifically designed for the purpose of improving the performance and convenience of Mirtec’s complete line of AOI machines. INTELLI-PRO consists of a proprietary deep learning-based automatic part search and teaching function; AI-based automatic parameter optimization; character recognition (OCR); foreign object detection (FOD); placement inspection algorithms, and an automatic defect type classification function.”

Inspection system for automotive electronics

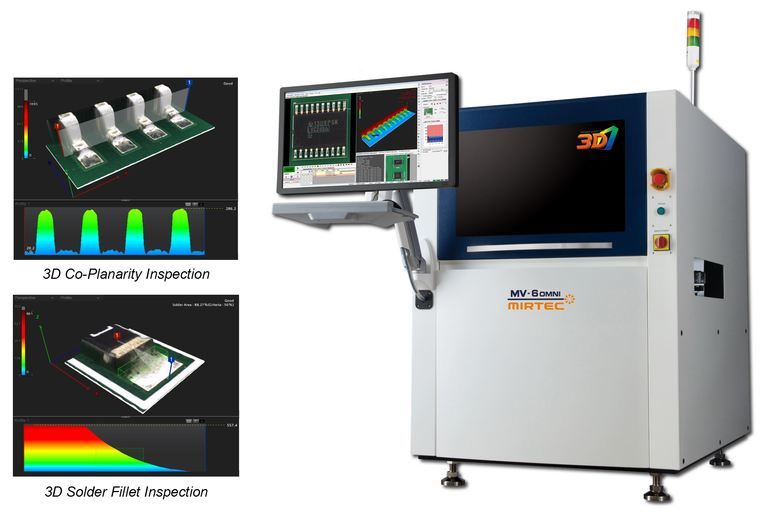

The company will also display its GENESYS-PIN inspection system for automotive electronics products. “It is configured with a 12 Mega Pixel CoaXPress High-speed Camera System with 15um Lens, Nine (9) Phase RGB Color Lighting System, long stroke Z-Axis, and four (4) of programmable multi-pattern digital projectors that is used for hybrid 3D measurement technology,” the company said.

“With this revolutionary optical system, the GENESYS-PIN machine can measure 50mm height connector pin, single pin, pin array, press-fit pin, and fork pin while maintaining high accuracy. Plus, it finds types of defects such as missing, offset (bent/tilt), distance between pins and inner/outer diameter of fork pin. The GENESYS-PIN machine operates in two different modes. One for precision inspection and the other one is for fast inspection. From zero to 12mm there’s no difference between two operation modes. In Precision Mode, when the pin height exceeds 12mm, the Z-axis attached to optical head rises the head, so that it can measure pins with precise accuracy up to 50mm. On the other hand, in High-Speed Mode, the Z-Axis never moves, and height measurement is limited up to 40mm, but the inspection speed is increased approximately 53% compared to the Precision Mode. It’s less accurate compared with Precision Mode, yet it is more precise than normal 3D AOI machines.”

Hall A2, Stand 461