Machine Vision Products, Inc., a leader in Automated Optical Inspection for microelectronics, semiconductor, and SMT assembly will be demonstrating their latest Microelectronics inspection solutions and quality management software at productronica.

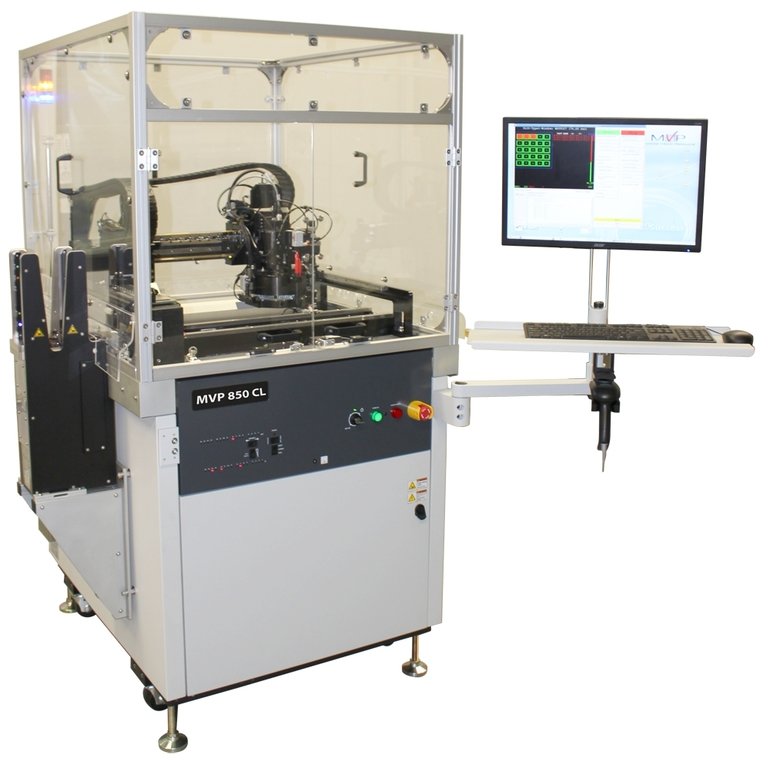

Visitors will be able to see the 850G Automated Optical Inspection solutions for microelectronics test. The latest version provides enhanced tools that achieves the highest defect coverage for wire bond, die, and wafer applications, presented in lead frame, tray, or wafer format. Using the 6.6 software and the multiple sensor technologies available on all of the company’s Automated Optical Inspection systems, inspection and metrology is now provided for any requirement. Inspection techniques include high-resolution telecentric imaging, quad color lighting, and 3D techniques to provide the maximum defect and measurement capabilities.

Being introduced at this year’s show is a new version of the AutoNetworker, a centralized database with the flexibility to be configured for a host of microelectronics and SMT traceability needs. It is also possible to record images, parametric and attribute pass/fail data for every product. The latest image archiving capability allows customers to have the ability to save every defect image from multiple AOI systems. For demanding processes where quality is of a critical nature, the ability to provide this visual traceability in addition to data traceability is essential. This also allows to create quick reports for quality managers, operation managers, and process engineers via a web-based interface that can be accessible from any intranet location.

Additionally, discussions and demonstrations of the company’s other key technologies will be available at the show, including:

The 2020 DWMS (Die Wire Metrology System) is a dedicated lead frame inspection Automated Optical Inspection system that uses advanced optic and handling solutions to provide the latest in die and wire bond inspection. This system is configured as standard with integrated lead frame magazine loaders and unloaders designed for error free operation at the highest of UPH demands.

The company’s Spectra system is capable of inspecting 35” x 35” boards, and even larger boards with board staging. In addition, the system provides robust material handling to allow the inspection of the heaviest of products.

The Supra E and Ultra V systems are the AOI workhorses of many high-volume manufacturers world-wide. These platforms provide cost effective AOI solution for all Surface Mount manufacturers with PCBs of up to 20” x 20”. The solutions provide 2D/3D AOI capabilities for SMT and paste inspection.

productronica, Booth A2.270