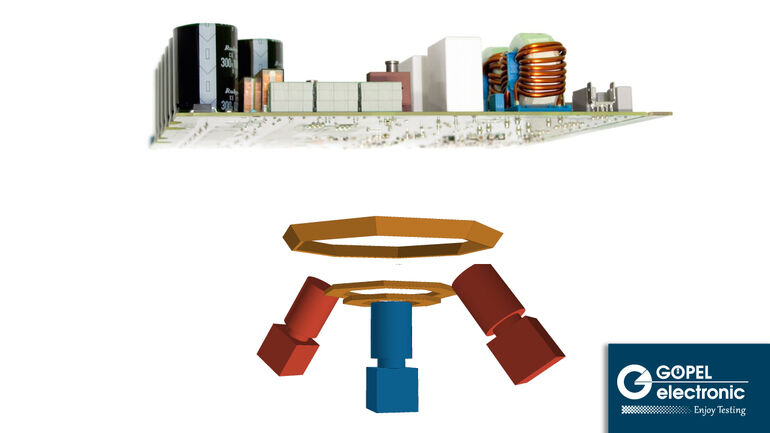

Göpel electronic, specialist in THT inspection systems, has announced the introduction of its new THT Line 3D system which features a 3D camera module. The company says the new system significantly reduces the false call rate when measuring critical THT solder joints and considerably reduces test time.

The camera-lens combination is characterised by high-resolution image acquisition, a larger field of view (FOV) and an increased image capturing speed. In addition to the 3D measurement of THT pins and its solder joints, this higher resolution makes it possible to inspect SMD components up to the package size 0201. Especially for selective soldering, this allows the inspection of SMD components which are close to the THT solder joints.

This camera module also features a telecentric lens with a measuring range of up to 35 mm, which is advantageous when using different carriers in the production process. As the PCB-A level can vary by several millimetres in relation to the transport level in such applications, this new camera module has no longer any limits for both 3D measurements and 2D inspections.

Reflex reducer

Solder joints that are steep, shiny or closely spaced can cause reflections, which may lead to incorrect height information during 3D measurements. Although the data can be corrected using various interpolation methods, it does not necessarily correspond to reality. To avoid this, the company has integrated a Reflex Reducer into the new 3D camera module, which eliminates this side effect and increases the reliability of the 3D measurement.

The THT Line 3D enables the inspection of THT components, THT solder joints and SMD components in one system. Assemblies can be fed automatically or manually with or without carriers. The PILOT AOI system software offers the user a high level of operating convenience and maximum failure detection thanks to different inspection methods. The proven MagicClick tool generates a production-ready inspection program including the component library in just a few minutes.