At productronica, Goepel electronic presented fully automated inspection solutions, offering high fault detection, flexibility, and cost reductions through time savings.

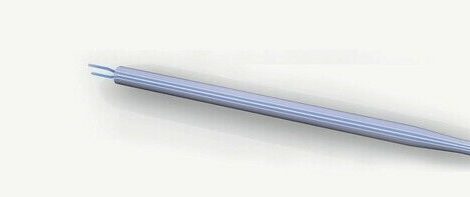

The main highlight was the Stingray x-ray detector, an additional option for the system family X Line 3D. With a highly flexible image acquisition concept consisting of high-speed axes and a flat-panel detector, selective 2D, 2.5D and 3D x-ray inspection of complex PCBs is possible. The technology ensures even better layer separation and brighter images, especially in 3D images, but keeps the balance between image quality and inspection speed.

Also, the system software Pilot AOI was premiered with the feature, MagicClick, which enables fully automated creation and optimization of AOI test programs, including component library, using a sample PCB. In only about 3 minutes, a production-ready test program can be generated. In comparison to the conventional approach, this feature offers significant cost savings and allows the use of AOI even for the smallest volumes. It is presented as part of VarioLine 3D, the AOI system for full 3D measurement of solder joints and components using an additional 360° angled-view.

Pilot Connect, the core of inspection solutions being offered in support of Industry 4.0, provides the most flexible MES connections. In combination with Pilot Supervisor, centralized verification of all inspection results from multiple inspection systems and types in the line becomes reality.

Scanflex II Cube is the new generation of JTAG/Boundary Scan controllers for board level embedded test, which is based on multi-core processors and FPGAs. The boards own circuitry is used for test and programming of complex boards with greatly reduced physical access requirements. With its multifunctional architecture, it supports numerous applications.