The new MatriX XCT-1000 system is especially designed for the manual CT analysis and offers highest possible flexibility for specific customer requirements. Depending on the customer application the system can be configured with different high resolution x-ray tubes ranging from 160 kV to 225 kV and with flat panel detectors with inspection areas up to 200 mm x 200 mm.

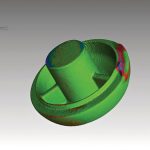

The XCT-1000 is capable of performing the classical X-ray transmission inspection as well as the CT X-ray analyzing. The industrial computer tomography guarantees complete, non-destructive analysis of objects with inner structures that are difficult or impossible to access. The compact, manual XCT-1000 system with a floor space of 1500 mm x 850 mm is ideally suitable for the operation in a laboratory environment as well as for material analysis (void and crack detection) of small series in the production environment of castings made of light metal, plastic or ceramic. The system is equipped with a highly precise 5 axes motion system. The checkable volume supported is 400 mm x 400 mm x 300 mm. To avoid gravitation influences the system’s x-ray beam path runs in horizontal direction and the rotary table does have a vertical rotary axis. With its horizontal beam path and the rotary table with Z-axis motion, the system meets all requirements to perform high quality CT techniques. Those are Fraunhofer Helix CT technique for artifact reduced high-performance CT and alternatively the Siemens Cera TXR (Theoretically eXact Reconstruction) technique for theoretically exact reconstruction providing reduced reconstruction times up to 50 %. Both methods are optionally available in combination with the standard MIPS-CT setup and offer a significantly higher CT quality, free of Feldkamp artifacts.

For visualization of the volume data the approved Volume Graphics VGStudioMax2.1 Software is used. The 2D and 3D analysis tools available are e.g. manual measuring of voids, porosities and wall thickness in volume as well as in slice images. The Matrix proprietary MIPS_NDT Software is used for control of the XCT-1000 system. It can be optionally extended by the modules MIPS_NDT analyzer and MIPS_NDT inspect. MIPS_NDT analyzer is used to perform manual analysis and image processing in X-ray images and slices. MIPS_NDT inspect is a software for auto- matic defect analysis with good/bad classification of X-ray iamges and slices. It supports also automated inspection of production batches.

Share: