With its tin-copper-nickel-germanium alloy SN100C now firmly established as one of the global electronics industry’s most popular lead-free wave soldering alloys, Nihon Superior announces that it is extending the range of material forms in which the alloy is available. Although developed initially to address the need for an economical wave solder, it has since been found that its properties also make SN100C an ideal choice for reflow and hand soldering as well as spheres for the attachment of area array packages. The fluidity of SN100C, which is comparable to that of tin-lead, is one of the factors that contributes to excellent through-hole fill and minimal shorts in wave soldering. However, that property is also an advantage in hand soldering where, in combination with the right core flux (030), it makes possible the completion of more than 35 average joints per minute with a tip temperature of only 380 °C. Nihon Superior is now offering the new eCore low-spatter lead-free flux-cored solder wire. The 227 °C melting point of SN100C was first thought to preclude its use in reflow soldering but when it was noted that tin-silver-copper alloys (such as SAC305 with a melting point of 217 to 218 °C) are typically reflowed with a peak temperature around 245 °C it was realized that SN100C could be a drop-in replacement. Its high fluidity and excellent wetting properties mean that SN100C can be reflowed successfully at a lower superheat above liquidus than SAC alloys. Nihon Superior now offers two types of SN100C solder paste — no-clean ePaste for general reflow purposes and ePaste, a special low voiding paste for critical applications such as die attach in which heat transfer though the joint must be maximized.

As an additional ePaste, SN100C will now be available as a high-performance solder paste with a general purpose “P500” flux medium. Because of its high fluidity close to its melting point and fast wetting, SN100C P500 can be used as a drop-in replacement for SAC solder paste in reflow profiles that peak around 245 °C ± 5 °C. The P500 no-clean halide-free medium delivers reportedly very good printability, long stencil life, good tack, excellent reflow and wetting on all substrates with no solder balls and minimal clear residue.

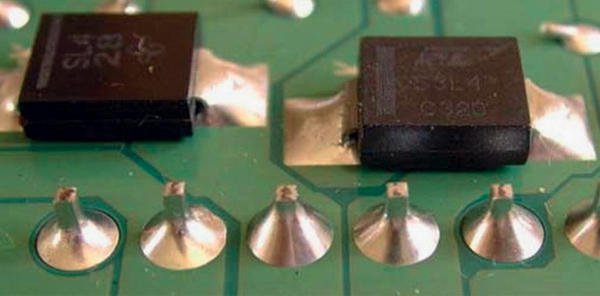

Advantages of the tin-copper system include its ruggedness in impact loading and the nickel addition provides inhibition of the intermetallic growth that can increase the susceptibility of joints to failure in shock loading, e.g. when a mobile phone is dropped. These properties are prompting the industry to evaluate SN100C in flip chip and area array packages, and the company is supporting this new application by making a range of eBalls available.

While a wide range of fluxes can be used successfully in wave soldering with SN100C, Nihon Superior also is now offering eFlux, a new flux that has been specially formulated for optimum results.

A solution for the lead-free HASL Process, SN100CL features excellent fluidity — good drainage ensures no bridges even on fine-pitch circuitry, good penetration of small diameter holes, uniform coating thickness and a smooth, bright finish. SN100CL wets quickly and offers low copper erosion. SN100CL forms a stable intermetallic compound layer (Cu/Ni/Sn layer) in between solder and copper laminate.

EPP Europe 428

Share: