The relatively young company history of machine and automation specialist Asys, founded in 1992 by Klaus Mang and Werner Kreibl who are also the general mangers, is in some ways a success story of brilliant engineers. Within a short time they enlarged the headquarters, founded one business unit or local service, sales and support facility after the other, from Singapore to Brazil and Finland for example, from cleanroom to metal surface treatment and solar cell production equipment. And because of their remarkable automation, handling and manufacturing machines and modules, and the precise, high-quality workmanship delivered, they were also the extended workbench for many other companies not having or building up expertise in this area of skills.

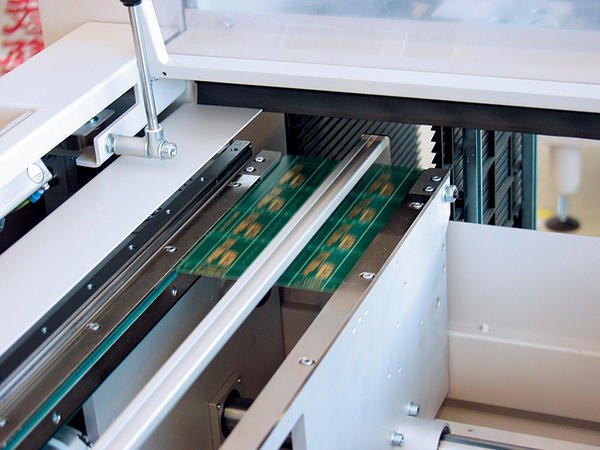

And they also took over the Ekra printing systems business in 2005 when this specialist company with its high potential went into serious financial trouble. This way the German enterprise Asys, located in Dornstadt near Ulm, became a well-recognized global player and is still privately owned today. For the linking of the different printer machines and the other equipment in the Benchmark Arena, Asys has contributed four different modules. The TRM 01–04 unit is based around a twin-belt conveyor segment with one adjustable and one fixed side. The frame features adjustable feet, an integrated switching cabinet and a table supporting the transport mechanism. The move of the PCBs can be provided in clocked or synchronous modus. The conveyor speed is either adjusted automatically or through the line configuration. The control frequency is being displayed as well as the current counter reading. The same software is being used for 1 to 4 segment units. Other main features are: input interface can be blocked (if line is to run empty); buffer function can be switched off; different conveyor lengths; transport height 950 mm ± 50 mm; and adjustable print control (to monitor the transfer from the previous unit such as a printer). The AES 03 D magazine unloader is equipped with a platform for two magazines. The unit pulls the PCB out by a built-in extractor onto a receiving conveyor. Using a shuttle mechanism, the receiving conveyor moves sideways into position and transfers the substrate to the next unit. More main features are: automated switching to the second magazine; a vertically aligned magazine clamping mechanism; different magazines used without modification; programmable transfer position; double track mode; electrical width adjustment; multiple output; reinsertion mechanism; universal magazine clamp; and dual-lane. The AMS 03 D magazine loader has the capacity for two magazines. PCBs arriving from the transfer conveyor are transported with a shuttle mechanism into position for one of the magazines. A pusher then slides the PCBs into the respective magazine. Other features are: automated switching; magazine platform vertically aligned; multiple insertion; and control function on inlet conveyor. The AEM 02 transfer unit is being used to connect corners or crossings. The module consists of a conveyor with a turning and a linear drive. The PCB is transported from the previous unit and can pass directly through the machine, or can be turned and then passed to the following unit. More main features: symmetrical cross construction; input and output can be individually configured; sorting function; buffering; fixtures for connecting input/output conveyors on all four sides; electrical width adjustment; loading lift for magazine; inlet/outlet conveyor; 90°-mode; fail/pass sort; and change of fixed rail. (gbw)

SMT, booth 7-639, 7-550, 8-205

EPP Europe 402

Share: