The selective soldering of assemblies in panels is not a real challenge. However, if you need to solder relatively large panels with towering components, specialists like those at Eutect have to step up to the plate. The experts for selective soldering automation have developed a complex special gripper on customer request, which reliably meets this challenge.

“In this particular case, it was a relatively large PCB that was divided into four panels. Two THT capacitors had to be soldered to each individual panel, which were not allowed to bend during the process. As these were very large and high, they were quite unstable in their unsoldered state,” recalls Matthias Fehrenbach, Managing Director of Eutect GmbH. The challenge was to prevent the large circuit board from bending and to keep the capacitors in position. “A standard inline mini-wave process was therefore out of the question,” says Fehrenbach.

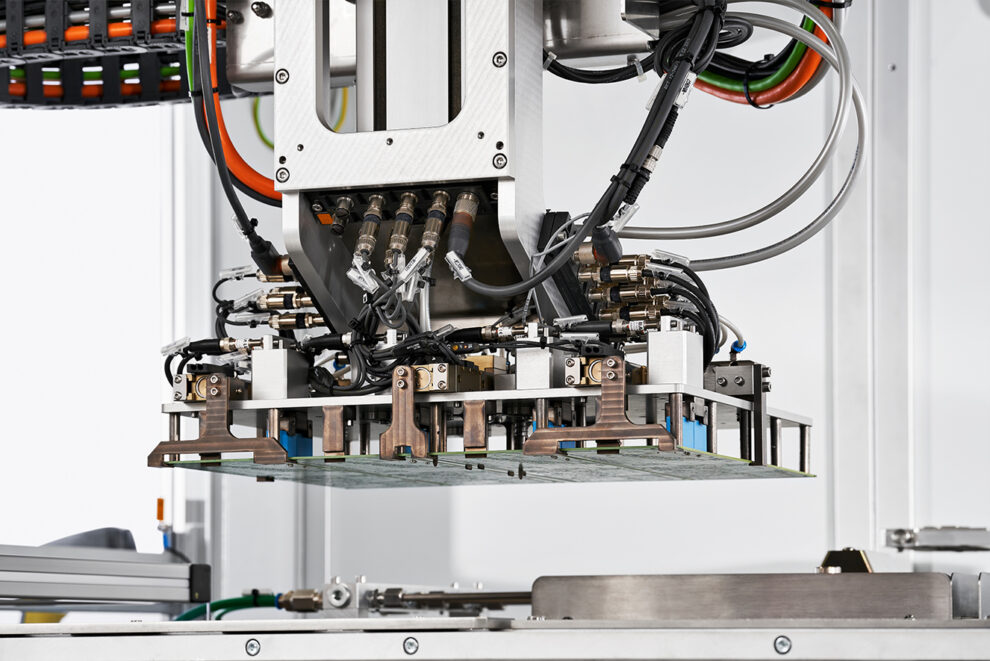

The process specialists at Eutect therefore developed a special gripper that both holds the components in position and prevents the PCB from bending. “Our customer specified that no bending force should act on the components. It was therefore necessary to feed the assembly absolutely straight to the respective processes,” recalls Lars Iwers, sales representative at Eutect, and continues: “The special feature here is that the panel arrived on the conveyor belt in the process cell without a workpiece carrier. However, as the component spacing was positioned too close to the belt, we could not solder directly under the belt. The panel therefore had to be picked up from the belt.” During pick-up, the PCB is pressed against spacers from below and thus held absolutely straight in the gripper. The upright capacitors were also pressed against component-specific hold-down devices. The gripper then moves to the IW 1 mini wave soldering module with a specific soldering nozzle using an axis system. A titanium mask was mounted above the nozzle of the mini wave soldering module to protect the circuit board, which is moved to the soldering position using a spring base mechanism.

“The fact that we had to move a PCB panel without a workpiece carrier in this project required the gripper to have a special configuration. After all, a panel like the one in this case is relatively unstable, which is not very helpful for a reproducible soldering process,” continues Fehrenbach. Therefore, attention was paid to ensuring that the gripper feeds the PCB panel into the soldering process in an absolutely stable and horizontal position. In addition, the gripper we developed allowed us to avoid the need for a soldering frame, which in other cases stabilizes the panel during the soldering process. “This allowed us to fully meet the customer‘s specifications. Thanks to the special gripper, it is now possible to guarantee a reproducible and cycle time-optimized process,” says Fehrenbach.