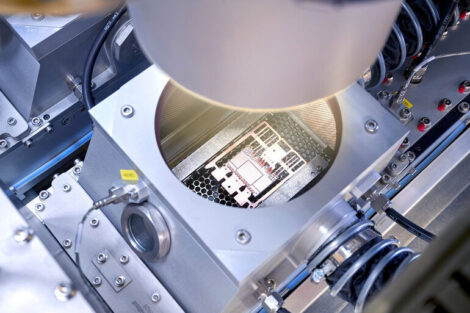

Esmo group (esmo), a global full-service systems integrator, developer, and supplier of advanced automation solutions, has introduced the Apollo Quad Handler. Designed to bridge the gap between the engineering and production phases, the company says the handler offers unprecedented flexibility, reliability, and energy efficiency for final test operations, setting a new standard for semiconductor testing.

“As semiconductor manufacturers continue to face increasing demands for greater throughput and efficiency, our new quad handler responds to industry needs with a state-of-the-art solution,” said Simon Murnauer, Manager R&D of esmo AG. “We are excited to introduce a handler that not only delivers superior performance, but also addresses critical issues like energy consumption and cost-effectiveness for applications where ultra-high parallel testing isn’t required.”

The success of esmo’s talos engineering handler sparked demand for a similarly flexible and reliable machine optimized for higher volumes. The new quad handler addresses this, offering an alternative to energy-intensive legacy systems. Optimized for testing complex devices like SoCs and AI chips, it’s designed for applications requiring up to 50,000 devices per day, delivering precise thermal performance and real-world UPH (units per hour) efficiency.

Key features

- Universal I/O Interface: Supports tray, tube, and tape loading/unloading with flexible module configurations, AMR/AGV ready

- Adaptable Device Pitch: Easily configurable for different pitches through conversion kits, minimizing costs by reusing existing loadboards and sockets.

- Versatile Device Range:

- Quad-site: Supports devices from 2.5 x 2.5mm to 50 x 50mm.

- Single-site: Handles larger devices up to 125 x 120mm (JEDEC tray size).

- Energy Efficiency: Uses 200 l/min CDA and 8 l/h LN2, reducing operating costs.

- Ultimate Thermal Control: Plunger temperature range from –80°C to +225°C for precise testing.

- Quick Conversion Kit Changeover: Tool-less and fast, with automatic kit-specific parameter transfer from kit to machine via RFID tags.

- Mixable Media Options: Allows flexible handling, with mixable media configurations (e.g., tray in, tape out), reducing additional inspection steps.

Another key feature is its seamless integration with existing automated test equipment (ATE). It can adapt to legacy handler-specific hardware interfaces, such as loadboards and site pitches, allowing users to upgrade their test cells without having to invest in new hardware.

“Our product meets the evolving demands of the semiconductor industry by delivering similar UPH at significantly lower costs—both in terms of purchase price and ongoing energy consumption,” added Murnauer. “It’s a solution that addresses both the needs of low- to mid-volume production and engineering trials, making it an attractive option for a wide range of customers.”

The handler supports flexible I/O module configurations, including tray, tube, and tape, allowing customers to transition seamlessly between testing formats without extensive downtime. With its modular design and tool-less conversion kits, the machine can be configured on-site in less than 5 minutes.

Additionally, the handler’s real-time monitoring capabilities continuous data tracking, with adjustments implemented immediately and detailed reports generated automatically, simplifying the process of maintaining peak operational performance.

“Apollo offers a scalable solution for medium- to large-scale engineering and low- to mid-volume production. Its higher throughput and flexibility make it the best choice for companies looking to optimize their testing capabilities,” said Murnauer.