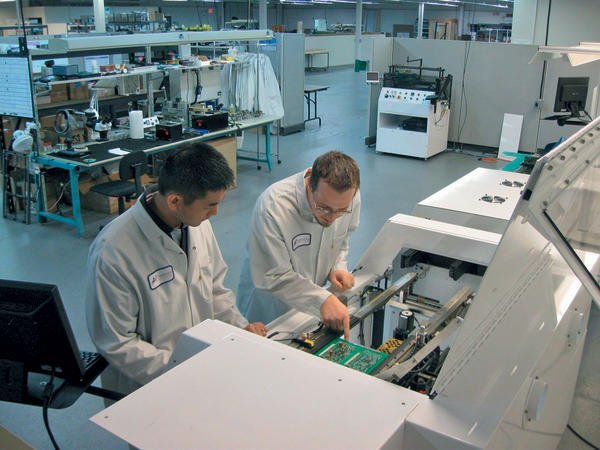

Achieving excellent results in selective soldering has as much to do with having a robust process as it does with using the right machine, according to A.C.E. Production Technologies’ President and CEO Al Cable. “That’s why we have invested so much in establishing our new selective soldering process development laboratory here at ACE. In the course of selling more than 300 systems, over the past few years, our process development engineers have developed and optimized soldering processes for literally hundreds of challenging assemblies. We want to share that knowledge. Delivering good solder results requires applied process knowledge as well as using capable equipment.”

The newly-opened lab is fully equipped with the latest soldering equipment as well as process development tools, thermal sensors, monitors, and more. The process Lab is equipped with all of ACE’s selective soldering tools, including traveling mini-wave systems, advanced solder fountains, spray and drop-jet fluxing systems, the new LTS 200 Lead Tinning system and a nitrogen generator.

The Lab is also equipped with X-Ray equipment and Solderability (wetting balance) and Cleanliness (ionic) test systems. “In addition to building a better process for individual customers, we’re also working to build a better selective soldering process overall,” Cable adds. “That’s where much of this equipment, such as X-ray inspection capability comes in. We x-ray solder joints on test assemblies, for example, particularly those formed with the newer lead-free alloys, and different types of board configurations, to optimize the process and better configure our equipment to produce high yields and consistently good results.”

Process development services are provided at no cost to new customers and ongoing development services are negotiated on an as-required basis. “Our customers have come to depend on our expertise to assist them with developing robust soldering solutions for their most challenging applications. The purpose of this new lab is, in large part, to determine the feasibility of a particular application and then identify optimal process parameters for it, and for difficult, and even not-so-difficult, selective soldering tasks.”

ACE Production Technologies is a designer and builder of simple, affordable selective soldering systems suitable for lead-free electronics assembly. ACE’s line of rugged, reliable selective soldering systems includes the KISS 101, KISS-102, KISS-103, and the KISS-104 models. All of these flexible systems feature lead-free compatible solder pots and are ideal for low to medium volume assembly, prototyping, and rework, post-reflow offline assembly, and other soldering applications such as odd-form devices.

EPP Europe 508

Share: