Altus Group, a leading distributor of capital equipment in the UK and Ireland, has introduced an advanced BGA re-balling solution to address the electronics industry‘s growing focus on sustainability and cost-efficiency. Developed by their supplier, Essemtec, this innovative process offers manufacturers a new approach to component recovery and reuse, aligning with increasing market demands for environmentally conscious practices.

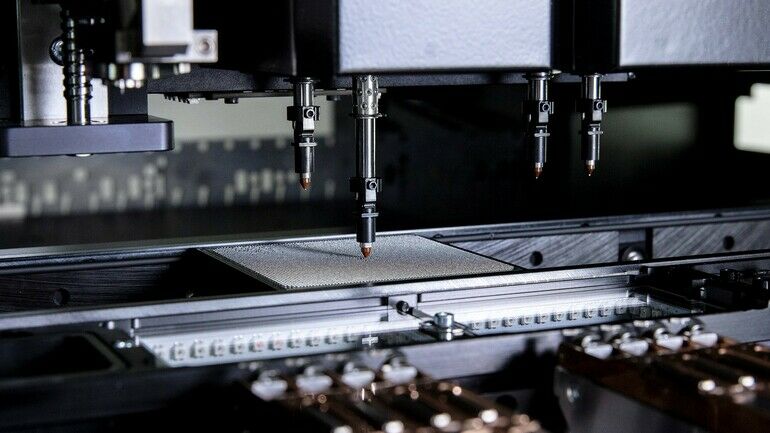

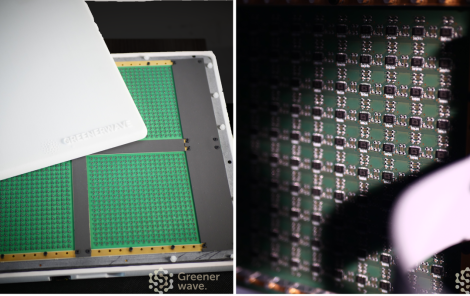

Building on their expertise in adaptive SMT equipment, Essemtec has designed a cutting-edge BGA re-balling process that consolidates flux deposition, ball placement, and soldering into a single streamlined solution. This all-in-one approach is particularly advantageous for high-volume OEMs and companies in sectors such as military, aerospace, computing, and communication, providing a cost-effective and sustainable method for component recovery and reuse.

“Reworking BGAs, recovery of expensive parts, and re-use is becoming a highly discussed topic across the electronics industry as consumers become more interested in sustainability,” said Jiri Kucera, Operations Director at Altus Group. “This is another example of Essemtec developing a process to meet the needs of the market.“

The new robotic process offers several advantages over traditional manual methods:

1. Increased precision and reliability.

2. Support for various ball sizes (250 µm to 1 mm+) and materials.

3. Improved success rates compared to manual stencil techniques.

4. Cost-effective reuse of expensive BGA components.

“Companies are already using the Essemtec jetting unit for BGA re-balling across a range of pitched components, giving partners the power to bring some of the recovery processes back in-house rather than outsource to partners at a higher cost,“ added Kucera.

This solution is particularly relevant for organisations prioritising environmental impact and sustainability. By extending the lifecycle of electronic components, the process contributes to waste reduction and promotes a more circular economy in electronics manufacturing.

Altus sees this technology as a significant step in meeting the electronic industry‘s evolving needs. As sustainability continues to gain importance, solutions like this will play a crucial role in shaping the future of electronics manufacturing and repair.