Provider of MES platforms Aegis Software, has launched a comprehensive manufacturing material management suite, “Lean Material Management Anywhere”, available on a new platform and device-independent architecture.

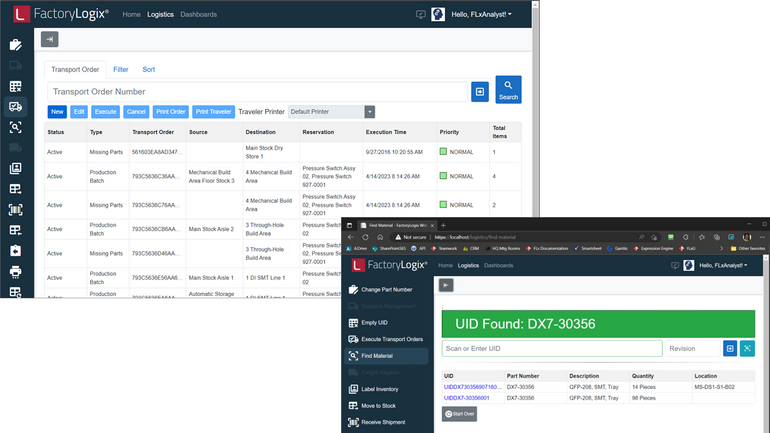

Lean Material Management Anywhere is a module within the company’s FactoryLogix IIoT-based Manufacturing Operations Management platform. The ‘Anywhere’ architecture addresses the need for flexibility, security, and ease of deployment for its FactoryLogix manufacturing material management solution. A single web-based architecture supports any mix of cloud, hybrid, and on-premise solution services, with no need for software installation, configuration, or maintenance on clients, eliminating significant risk and cost of ownership. Each client has an open choice of devices and operating systems as deemed appropriate for each user instance. Self-configurable user interfaces focus on their specific roles, satisfying specific use-case requirements.

“Our customers‘ material management needs are complex, requiring support for the most varied and stringent needs,” said John Walls, Co-Founder and Chief Technology Officer at the company. “We designed the Lean Material Management Anywhere solution to be easily deployable on any of their chosen devices, and cover all key materials storage, logistics, consumption gathering requirements, etc. using simple configuration, rather than customization with code.”

FactoryLogix Lean Material Management Anywhere features many key material management functions within a single web-based environment, including material receiving, inspection, warehouse and local storage management, logistics operations decision and control, and automation of Lean material management. Continuous monitoring of material consumption and spoilage enables Lean Material Management Anywhere to precisely govern inventory management levels, with accountability back to ERP for each individual piece of material, with full ‘digital thread’ traceability. The real-world values and benefits of manufacturing material management are broadly valued when external material supplies may be short or customer completion requirements suddenly change, representing the difference between being able to execute and complete work-orders or not.

“Material Management has become a huge area of value for our customers, who need stress-free visibility and control of their materials on a holistic, factory-wide basis, without the necessity for complex and restrictive software installation,” said Daniel Walls, Managing Director EMEA at the company.