At the SMTconnect 2019, Asys will show its complete range in the field of material logistics. The focus is on the intelligent factory – modularly combined and implementable in all degrees of automation. A highlight is the receiving station. Materials can be traced in production from the very beginning: the company offers a track and trace solution from goods receiving. In addition, storage, line supply and final assembly are core competencies that make the company a complete solution provider in the Industry 4.0 context.

Goods receiving: scenario for component roles

In the Asys receiving station, component rolls are labeled with a unique ID at a Scan&Label station. This ID is passed on to the higher-level system so that it can be assigned at any time in subsequent production processes. In addition, an X-ray cell can be integrated into the receiving station, which records the exact number of components on the component roll for process control purposes. In this way, inventories can be verified and reliable process planning can be created. Finally, the component rolls are prepared for automated transport and traceable storage by bundling them in containers. These containers, in turn, can be tracked at any time during production using RFID, so that all material flows during production can be monitored.

Access to software: important functions combined with user interface

With the Pulse user interface, many of the company’s software options can now be accessed flexibly and device-independently. It integrates the previous Pulse applications such as „Alerts&Info“ and „User2Machine“, as well as many additional functions for process machines. The „Operation“ app can be used to display the user interface of the machine, at Asys the Simplex HMI, so that remote control of the system via Pulse is possible. The offline programming tools that the company offers for depaneling and marking systems can now also be started easily via Pulse. Their software solutions are thus combined on a central user interface in order to further simplify planning processes in production.

Four criteria of the Smart Machine

At the SMTconnect, the company will present for the first time a Smart Machine. Four criteria drive the development of smart machines into the future:

- Intelligent: The machine is capable of autonomous operation and adapts its behavior on the basis of experience gained.

- Secure: The machine is capable of preventing and correcting faults during operation, largely independently of operator instructions.

- Managed: The machine is capable of learning and predicting future events and evaluates the „machine state“.

- Connected: The machine is capable of contacting and interacting with other machines/systems.

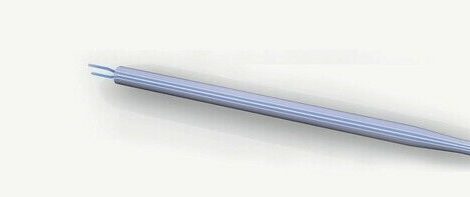

The company has further developed the Divisio 5100 based on these four criteria, in order to meet the requirements of a „Smart Machine“. At the tradeshow, the depaneling system will be presented in this context. It offers a monitored process thanks to a force path-regulated gripper system, delivers ideal cut edges through intelligent and dynamic cut positioning, networks with an offline programming station for uninterrupted product change on the line and supports predictive maintenance so that maintenance cycles are initiated as required.

SMTconnect, Booth 4A-324