MOSFETs are superior to reed relays in many respects. Those continuing to use traditional relays because of their low current leakage are missing the benefits offered by alternative solid-state components.

Benefits of MOSFET relays

MOSFET relays deliver substantial benefits for test equipment. They take up less space on boards, offer faster switching times, and provide longer service life than traditional reed relays. Many applications also benefit from the lower power requirements, stable on-resistance and better resistance to shock/vibration they provide.

One of the key benefits of MOSFET relays is their package size. Reed relay packages, placed in high volumes on PCBs, require much more space. Increasing demands from the semiconductor industry, test equipment with a more advanced design, and higher integration needs all affect the number of inspection channels. All these extra requirements are transferred into a larger number of switching components. Using more compact MOSFET relays can thus make a huge difference in terms of the amount of board space utilised.

Then there is the question of reliability which, in turn, translates into operating life. In test applications, reed relays need to be regularly maintained. Mechanical relays have generally been preferred in the semiconductor industry (as well as for other test equipment) – in part due to their isolation characteristics. They do, however, have a shorter lifespan due to abrasion of the contacts – which reduces equipment durability over time. When used intensively, mechanical relays need to be regularly replaced – pushing up maintenance costs. Moreover, replacement is necessary as soon as contact resistance goes above a specified threshold, and this end-of-life moment is not easy to predict or evaluate.

Alternative solid-state relays provide incomparable electrical endurance and, when used with semiconductors, do not suffer from mechanical contact wear. There is thus no need for maintenance. Nonetheless, there are still some performance trade-offs when using these alternative relays. These are summarised in the table on p. 56.

Leakage current – a barrier to adoption?

Though used advantageously in many applications in test equipment, MOSFET relays, like reed relays, are stretched to their limits by increasingly demanding test requirements. Despite boasting exceptional reliability and tiny packages, to meet the needs of the T&M industry, they must also deliver in terms of performance. One of the most critical ratings for semiconductor components is leakage current. During DC parametric testing in automatic test equipment (ATE), for example, minimizing leakage current at the test line is a key factor to ensure accurate measurement. Increasing drain-source voltage results in increased leakage currents. This creates issues with performance values. In circuit designs where multiple lines are used, such as semiconductor devices switching various DUTs and measurement pins, MOSFET relays can reach their limit.

Are T-modules the solution?

Using T-circuit solid-state modules, however, it is possible to address leakage current issues associated with MOSFET relays. These modules are based on a T-circuit built on three MOSFET pairs (as shown in the diagram on p. 55). This design facilitates a higher degree of control over leakage current. As shown in the diagram, the leakage current flows to the ground via a central joint when the relay is in the OFF position and the primary line is open. The result is a substantially lower level of leakage from the DUT than in a standard circuit configuration.

The technical construction centres on MOSFET pairs and enables effective control of the leakage current, delivering minimal levels of pA or even fA. The Omron G3VM-21MT module, for instance, specifies a maximum leakage current less than 1pA at VOFF 20V. Real-world values are usually lower by a factor of ten. This indicates that T-circuit solid-state modules represent a real alternative to conventional solutions provided by reed relays in terms of measurement performance.

Reference design is encouraging

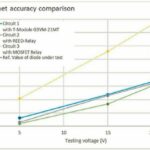

A reference design is available to help design engineers evaluate the impact of transitioning from reed relays to these new T-circuit solid-state modules. The aim of this is to show the value of MOSFET relays in standard and T-circuit configurations and reed relays on the same board under identical conditions. Comparison of measurement accuracy can be achieved across mature mechanical reed relays, MOSFET relays and the MOSFET T-module.

The reference design highlights further differences between these options and reveals the value of the T-module. The results (shown in the graph on p.55) prove that levels of leakage current from T-module and reed relays are almost same as the reference value from the DUT diode.

One of the key attributes of G3VM-MT modules is their performance at higher frequency levels. While continuing to offer reliability and durability like other MOSFET relays, these modules also deliver further positive characteristics at higher frequencies.

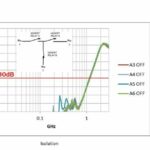

As shown in the diagram, results from the G3VM-21MT confirm that a device with a high reliability, small size and extremely low leakage can offer outstanding RF performance. Its isolation performance is less than –30dB at 1 GHz and the insertion loss is more than –3dB (see graphs on p. 56).

The combination of benefits offered by MOSET relays and mechanical relays mean the G3VM-MT series is suited not only to ATE solutions, but is also worth considering in other applications.

More than a component

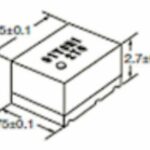

With their T- circuit structure, Omron’s G3VM-MT MOSFET modules demonstrate exceptionally low leakage current, giving accurate measurements in all types of test equipment. Their compact size (5mm x 3.75 mm x 2.7mm), achieved by incorporating the MOSFETs into the module, allows for simpler PCB board design owing to the elimination of crossovers in PCB tracks and simplified wiring patterns. The device is designed for surface mounting and offered in SPST-NO form with ambient temperature ranges above 100°C. New solutions include a high current and high voltage model (as seen in the diagram and graph above). Together, these specifications help pave the way for wider use of T-circuit MOSFET relay modules.

In summary, these modules offer maintenance-free operation and a simplified design that saves space on PCBs as well as great measurement performance: contributing to industry progress and adding value for the customer.

Electronica, Booth A3.538