The productronica 2017 show was successful for the company, Feinmetall. They were happy with the large attendance of customers and potential buyers from all over the world. One highlight this year at the show was the light contact probe – a contact probe with integrated LED. This solution allows optimizing wire harness modules for cable assembly: an LED in the contact probe indicates the cavity for the terminal insertion and directly after the assembly a continuity check can be made.

There was also great interest in the live measurement of the radio frequency probe family HF66 with an outstanding transmission performance and a special probe design that allows reliable contacting of connectors (e.g. cable connectors or switch connectors) even if they are not perfectly positioned.

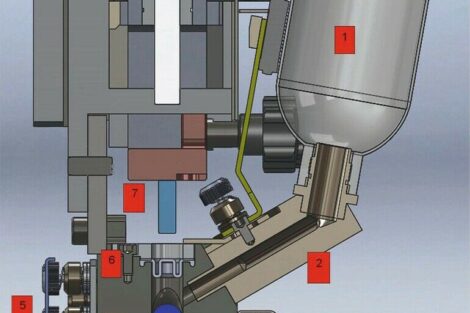

Also, a live presentation showed the variants of the position sensor system, that is now available in smaller centers of 75 mil and as a more robust and airtight version for centers of 157 mil. Position sensor systems are contact probes with integrated potentiometer. They allow a quantitative determination e.g. of the position of a component, the length of a pin, or the depth of a hole.

Many visitors have also been impressed by the high amount of new fine pitch probes that are mainly used for contacting semiconductor components and nearly invisible to the naked eye. The market needs in this segment are currently rising rapidly. Since components are getting smaller and smaller, the corresponding contact probes are also following suit. Key words like wafer level chip scale packaging are heard everywhere, the development regarding internet of things belong to the most important drivers of the electronic and semiconductor industry.

Further topics have been test contacts for standard interfaces like USB, RJ or HDMI. These test contacts can be mounted very simply and without soldering, a special design of the holding device leads to a reliable and optimized alignment with the DUT.