IPTE, a supplier of automated production equipment for the electronics and mechanics industry, exhibited at the IPC Apex Expo in San Diego, USA. The company focused on three main product categories at this exhibition: printed circuit board depaneling, laser marking, and function test/flashing with automated board handling.

They showcased the following products: EasyRouter depaneling system (off-line low-cost PCB depaneler), the easy test handler ETH (economical inline test/flash automation solution with compact footprint), MFT board handler (inline ICT/FT automation solution), FlexMarker (flexible inline laser marker with X/Y axes), and some EasyLine conveyor modules (BBL – Bare Board Loader and BTR-500 linking conveyor).

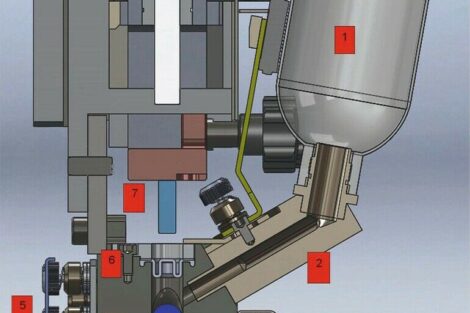

The EasyRouter system is equipped with a productive milling cutting tool featuring a depaneling speed of up to 60 mm/s for the fast separating of circuit board panels. This depaneling system is manually loaded and unloaded and features a two-position rotary table for simultaneous loading/unloading and panel separation.

The X and Y gantry drives are modern, fast and precise linear-motor axes. The EasyRouter further comes with a camera-based CATS (Camera Aided Teaching System) for fast and straightforward programming of the depaneling application. Moreover, the programming can also be done by importing standard DXF-files or G-data codes. Both capabilities are available for off- or on-line operation. The EasyRouter can be equipped with a collaborating robot for automated loading and unloading.

In-Circuit test, functional test, flash or boundary scan applications can be automated economically with IPTE’s test handlers. These are designed to use with single-circuit boards, multiple boards or carriers for printed circuit boards. Both one- or double-sided fixtures can be realized. The fixtures can be exchanged quickly and easily without the use of tools.

The ETH test handler can be configured with a bypass conveyor that allows panels to passthrough while a panel is being processed. This allows multiple handlers to be placed back-to-back to reduce overall cycle time.

IPTE’s FlexMarker design allows the processing of larger work pieces and is also the most flexible system in the laser-marker portfolio of the company. For handling and operation, the PCB is first clamped onto a segmented conveyor belt and then positioned by an XY-gantry in the required working area of the laser unit. This way, there are no accelerated or jerked movements in the system which would harm the performance of the laser optics. This working principle also assures a longer lifetime and higher process accuracy. The use of an X/Y gantry results in a significantly large marking area of 510 x 510 mm (20 ” x 20 ”).

IPTE’s presence at the Apex Expo is part of the company’s strong presence in North America. Since 1997, they have had its own subsidiary in the United States located in Alpharetta, GA. This location is fully developed as a production and development site for automated assembly.

Company contact

IPTE USA

6245 Shiloh Road, Suite B

Alpharetta, GA 30005 USA

Tel.: +1 (678) 807–0067

E-Mail: info@ipte.com

Website: www.ipte.com