Proper thermal management is needed to ensure the reliability of components that exhibit significant self-heating. Typical examples include LEDs in lighting applications and IGBTs and FETs in power supplies, converters, and motor drives.

Various techniques are available to extract and dissipate the heat from inside the component. The designer’s decisions can influence other important aspects of the end product, such as cost, size, and

appearance.

Attaching a heatsink, usually directly to the component itself, is a typical solution. There can be drawbacks, however. Depending on the power to be dissipated, the heatsink needed may be large and bulky. Active cooling, using a fan, may be required. In addition, attaching the heatsink during product manufacture may require special, or even manual, assembly processes that increase the cost of the end product.

Cooling through the substrate

Fortunately, there are alternatives. One is to dissipate heat into the substrate. This is a popular approach, particularly where surface-mount packages are used. Surface-mounted LEDs, for example, dissipate a high proportion of heat through the underside, to maximize utilization of the topside as the light-emitting surface. As far as power transistors are concerned, typical through-hole packages have design features that ease attachment and optimize dissipation from the die into a heatsink. Surface-mount packages, on the other hand, may be optimized for cooling through the topside, underside, or both.

Where heat is to be dissipated through the underside, the substrate must be capable of dealing with this. If the thermal properties of standard FR4 material are not sufficient, adding thermal vias filled with high-conductivity material can increase the ability to remove heat from the component package. However, this can increase the board cost and complicate circuit layout and routing.

A thermally enhanced substrate can help overcome these challenges and, in some cases, can allow a heatsink-free design. Insulated Metal Substrate (IMS) circuit boards provide high thermal conductivity and are available in various grades. Some manufacturers also offer economical non-IMS products that deliver thermal performance several times better than FR4.

IMS properties and parameters

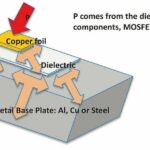

An IMS laminate consists of a metal baseplate separated from the circuit foil by a thin layer of dielectric, arranged to promote heat flow from the mounted component into the baseplate, from where it can be dissipated into the ambient environment.

The dielectric is resin-based and serves to bond to the metal layers as well as providing electrical insulation between them. The baseplate is often

aluminum, typically chosen for its light weight and relatively low cost. Various alloys are available that offer designers a choice of properties. Pure

aluminum has superior thermal conductivity and is relatively low cost. On the other hand, aluminum/magnesium/chromium mixes such as Aluminum 5052 – a medium-cost alloy – are better suited to processes such as bending, forming, and punching.

Alternatively, the baseplate may be copper and, sometimes, steel. Despite increased cost and weight, copper may be chosen where superior thermal performance is needed. It can also be chosen if there is a need for the baseplate coefficient of thermal expansion (CTE) to be closely matched with that of the circuit foil, to minimize mechanical stresses at elevated temperature.

The circuit layer is typically a standard HTE (High Temperature Elongation) ED (Electro-Deposited) foil, as used in regular copper-clad PCB laminates. Super-elongation foil can be specified where extreme CTE mismatch is an issue.

The dielectric layer may be a composite of epoxy resin with woven glass reinforcement, like a conventional laminate construction. Compared to conventional resins as used in ordinary FR4 laminates, its thermal conductivity is enhanced by loading with a thermally conductive ceramic filler. The conductivity can be controlled by adjusting the proportion of filler, up to a maximum of about 70%.

Despite the effects of the filler, the thermal conductivity of glass-reinforced materials is limited by the nature of the glass. For highest thermal conductivity, the dielectric may simply be a layer of unreinforced resin. This demands critical control in manufacture to maintain a consistent dielectric thickness, whereas the glass fabric provides a natural mechanical spacer. Note that whatever the proportion of ceramic filler, and with or without glass reinforcement, the resin must retain its ability to reliably bond the baseplate and circuit foil and withstand potentially severe thermal cycling conditions. In general, the reinforced dielectrics have lower thermal conductivity and higher breakdown voltage.

Another basic difference between reinforced and non-reinforced dielectrics is in their mechanical bendability, which allows post-forming of the substrate into three-dimensional shapes. This can help in applications such as automotive LED lighting, giving the opportunity to combine several elements into a single fitting while also simplifying the design and final assembly.

Choosing optimal IMS properties

By managing these variables – resin composition, glass reinforcement, dielectric layer thickness, baseplate material, and baseplate thickness – IMS manufacturers can present a portfolio of materials that offer various combinations of properties; particularly thermal performance, reliability, and cost. The image BILD2 compares the specifications of Ventec’s ‘tec-thermal’ family of thermally enhanced substrates. They cover thermal conductivity values ranging from 2.2W/m.K to 7.0W/m.K, which compares with 0.3W/m.K for standard FR4 material. The diagram includes the non-IMS substrate VT-5A2, which has thermal conductivity eight times better than FR4 and is aimed at cost-sensitive applications.

Typical maximum operating temperatures for insulated metal substrate laminates are about 130°C. Certain glass-reinforced grades can be as low as 90°C. High-Tg thin laminates and prepregs are available, capable of operation up to 150°C.

A simple and effective solution

An IMS can be a simple and effective solution to thermal management challenges, particularly in systems containing power semiconductors and LEDs. The opportunity to dissipate large quantities of heat energy through the substrate helps ensure reliability while at the same time permitting a space-saving solution. Depending on the application and operating conditions, IMS also helps design without components like heatsinks and other cooling devices such as a fan.

Various combinations of dielectric composition, baseplate material, dimensions, and circuit foil give IMS products a wide range of thermal – as well as electrical and mechanical – properties. These give designers a broad scope to optimize the characteristics to suit their application.

Don’t miss…

The second article in this series will examine practical IMS applications and guidelines for material

selection.