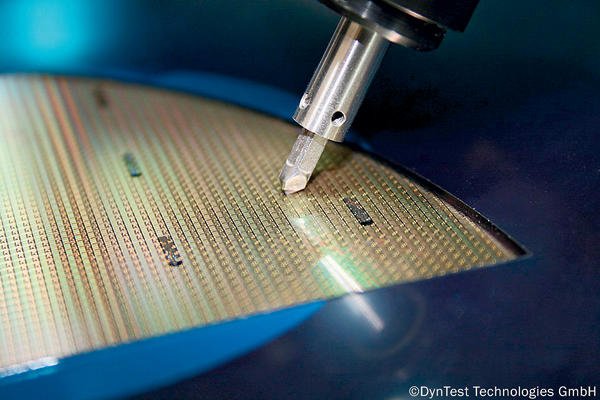

DynTest Technologies benchmarks with its high precision scriber/breaker DM-8150 excellent process performance and improved yield rates separating, that is wafers with backside metal and quite sensitive epitaxial material (VCSELs). The first benchmark performed concerned a wafer/device with a backside metal film. An application, according to the publication of a well known Laser-Separation-System manufacturer, a “no no” for a scriber/breaker. In fact, this may have been true to a certain extend in the past. ”It was quite obvious, claiming a 2nd generation system with enhanced process capabilities, to be challenged with applications quite difficult to solve with traditional scriber/breakers,” explains Joerg Lindner, Managing Director, DynTest Technologies.

The break module, developed by the company, is able to overcome these limitations and reduces the stress applied to the wafer. With this breaker module the break knife does not have to stop at the wafer bottom level, but it can slightly move further up, in between the two independent, Y-position programmable anvils. Having such new process feature available, the backside metal film has absolutely no negative influence to the break performance. The enhanced process performance allows a much wider process window and provides therefore a stable process achievable with a minimum of set-up effort/expenses.

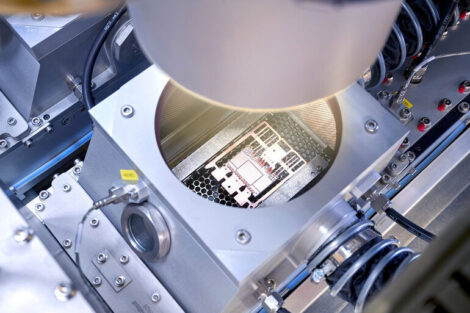

More challenging was the optimal set-up for the separation of vertical-surface cavity-emitted laser diodes (VCSELs). The brittle, vitreous surface of these epitaxial-wafers with dies at a size to thickness ratio below 1.5, like 200 x 200 µm at 150 µm thickness, is quite sensitive to any stress during the process. The DM-8150 provides enhanced capabilities to optimise the scribe/break process. These capabilities insure 100 % break rate, with minimal stress applied to the wafer during scribe and break, resulting in a remarkable reduction of chipping and consequently an improved process yield.

To keep the stress to the sensitive wafer surface as low as possible, a minimal, closed loop pressure controlled, scribe force is applied and scribe and break of the X-direction is completed before scribe and break of the Y-direction. This method keeps the stress force especially at the cross sections of the scribe lines to a minimum. In addition, not only different acceleration, speed and end points are used as break knife parameters in X- and Y-direction, but also different anvil positions are selected for X and Y.

The semi-automated system requests only very short operator interventions. This means one operator can easily handle more than one system, or run several other tasks in parallel, while operating the system. Part of the future road map in process development is an optimised, high throughput set-up for standard LED and RF devices, making use of the maximum scribe speed of 250 mm/s and the reduced break cycle time of approximately 0,5 s.

EPP Europe 443

Share: