The requirement to comply with the European RoHS regulations (Restrictions on Hazardous Substances) that restrict the use of lead, cadmium, mercury, hexavalent chromium, poly-brominated biphenyl (PBB) and poly-brominated diphenyl ether (PBDE) flame retardants, has driven the adoption of a range of new materials in electronics components. A company failing to comply with RoHS can be fined. Hence, to ensure only RoHS compliant materials are used, the industry has turned to energy-dispersive X-ray fluorescence (XRF) as a goods-inwards inspection tool. However, the technical capabilities of the related instruments are not well understood by the electronics manufacturing community.

In consequence, and in order to develop confidence in using the XRF technique, a jointly funded industry/DTI collaborative project, led by the National Physical Laboratory (NPL), has been undertaken to determine the suitability of these techniques for determining the presence and levels of any restricted substances in typical electronics components. The project focused on an inter-comparison of different XRF equipment and test sites in a matrix experiment.

X-ray fluorescence (XRF) is used throughout a wide range of industries for fast, non-destructive, elemental analysis of materials. Samples are bombarded with high energy X-rays and some of the X-rays are absorbed by the atoms of the sample. If the captured X-ray is of sufficient energy, an electron will be ejected from an inner shell of the atom creating vacancies. To stabilise the atom, electrons from the outer shells fall to the inner shells, giving off an X-ray whose energy is the difference between the two binding energies of the inner and outer electron shells. As each element has a unique combination of electron shell energy levels, the spectrum of emitted X-rays is characteristic of the elements contained in the sample. The peak intensities of the emitted X-rays provide information about the concentration of the elements present.

The incident X-rays are usually provided by one of two alternative sources: an X-ray tube or a radioactive isotope. The X-ray tube is inert until activated by the operator whilst the isotope source needs shielding to prevent operator exposure. Examples of both types have been included in this study.

The emitted X-rays are analysed using one of three types of detector.

- SiLi detectors: These have the best resolution, but require liquid nitrogen cooling to maintain their stability.

- Si-PIN photodiodes (formed from p-type/intrinsic/n-type semiconductor): These can be cooled using Peltier devices, are less expensive, but do not have as a good a resolution as the SiLi detectors. These detectors form the majority of the systems evaluated here.

- Proportional counters: These use photo-ionization of gases within the counters, to detect the X-rays. They are the least expensive of the options explored in this study and are widely used in the PCB fabrication industry for plating thickness measurements.

Initially, a range of samples known to contain RoHS-banned substances, was assembled by NPL. For each sample type, one sister specimen (that is from the same batch) was chemically analysed to determine its composition and the levels of any banned substances. The master sample from each batch was then given to each partner for “blind” evaluation using his own XRF systems. At each test site, therefore, the same sample was tested for each sample type. When all the XRF trials had been completed, the actual samples used were chemically analysed using mass spectroscopy and SEM electron-dispersive X-ray analysis to confirm its elemental composition. A range of nearly forty samples was used in the evaluation process, of which twenty-two contained RoHS-prohibited substances. The latter included Pb/Br/Cd/Hg in plastics (plasticizers/pigments) and lead in solders (bulk, joints and coatings). Additionally, fifteen RoHS compliant samples were included to help evaluate the performance of the XRF systems. Each sample was presented to the XRF systems three times, with the sample being removed from the equipment between tests. The XRF system parameters such as incident X-ray energy, analysis area (spot size) and emitted X-ray acquisition times, were set by the end-user/supplier consistent with his own best practice. In total, 15 systems (11 different instruments from 6 manufacturers) were tested: 11 bench-top instruments (7 Si-PIN, one SiLi and 3 proportional counters) and 4, less expensive, portable machines (all Si-PIN). All employed X-ray tubes as the source for the incident X-rays except one system, which used a Co 57 source.

RoHS screening of … … plastic components

In choosing plastic samples for these tests, a wide range of typical electronics components was evaluated before the final selection was made. During this procedure, it was noted that RoHS non-compliant components did not typically contain Pb, Hg, Br or Cr at levels around the RoHS limit of 1000 ppm. Rather, whilst typical values for non-compliant components were usually above 0.25 % (2500 ppm), those for compliant components were typically less than 0.05 % (500 ppm).

The Si-PIN or SiLi detector based systems were capable at identifying the non-compliant components containing lead, mercury or cadmium. Eight typical RoHS non-compliant plastics from electronic components were examined, and all twelve systems correctly indicated the samples were non-compliant. Three typical components containing bromine or chromium were also all correctly identified as containing these elements and hence requiring alternative tests for speciation of the hexavalent chromium and bromine compounds (PBB/PBDE/other).

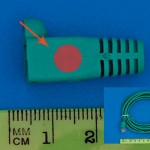

Three RoHS compliant components were tested, and all twelve PIN/SiLi systems indicated compliance for lead and mercury. Results regarding false negatives (that is incorrect indications of non-compliance) were also encouraging (see table 1). In the case of cadmium, both bench-top and portable XRF systems were able to distinguish non-compliant systems for levels above 1000 ppm Cd. All the false indications of non-compliance occurred when the XRF measured levels were between 100 and 260 ppm Cd. The three proportional counter based systems evaluated did not perform well for testing plastics. Although not specifically designed for testing for RoHS compliance in plastics, all the systems incorrectly indicated the presence of RoHS banned elements. Moreover, quantitative results were unavailable or inaccurate. It is recommended that proportional counter systems should not be used for RoHS compliance measurements. How the sample is presented to the test equipment is important. When a cable strain relief was tested whilst still attached to its accompanying cable (shown in figure 2), the lead level recorded was reduced by the effect of the material within the strain relief itself. In this instance, the lower results were still non-compliant, but should this example have had a lead content at a level closer to the RoHS limit, this modification could have caused the sample to have been incorrectly marked as compliant. Where recorded contaminant levels are close to the RoHS limit, it is recommended that the plastic be tested in isolation.

… of bulk solder alloys

For larger samples, large analysis spot sizes can be an advantage. Sampling over a larger area can reduce any effects of segregation within the sample and give a more meaningful analysis. For the lead-contaminated, bulk alloy samples tested, the Si-PIN/SiLi based XRF systems were able to at detect lead levels down to around 500 ppm. Some systems even achieved good repeatability at 50 ppm Pb. All the systems indicated non-compliance in all instances of lead present in tin at levels of 2000 ppm. At 1000 ppm Pb, 11 out of 12 systems indicated non-compliance for lead, or within 10 % of RoHS limit. Thus all Si-PIN or SiLi detector based systems proved suitable for screening bulk solder samples for RoHS compliance for lead, detecting lead at or above 2000 ppm. For levels between 500 ppm and 2000 ppm, additional techniques are recommended if accurate elemental analysis is required. Incorrect indications of non-compliance were again recorded for cadmium in Sn/Pb. Ten Si-PIN/SiLi systems were used to analyse cadmium levels and of these, 50 % gave false indications of non-compliance.

All the proportional counter based systems were able to detect lead in bulk solder samples at 0.2 % or above. Moreover, only one system was able to detect lead down to 0.1 %, and none was able to detect less than 0.1 % Pb. Some proportional counter based systems are not able to detect less than 0.2 % Pb in bulk alloy samples, and therefore care should be taken when using them for RoHS compliance screening.

… of solder joints

For the much smaller SM solder joints, the measurement window size (or spot size) is important. For accurate determination of the lead content, samples need to fill the measurement window. Moreover, solder joints by their nature tend to be thin, and the signal recorded may contain contributions from other materials beneath the solder joint.

Screening SOIC joints with large spot sizes: With Si-PIN/SiLi detector based systems, the spot size for portable systems tended to be greater than for the bench-top machines (at least 3 mm diameter). With the toe of the SOIC solder joints tested being approximately 0.65 x 1 mm, such joints only filled around 8 % of the measurement window of a typical portable system. A further complication is that the joint areas examined were not of constant thickness due to the shape of the fillets. Although one of the portable systems did indicate non-compliance for lead for a sample SOIC joint containing ~ 3 % Pb, the recorded values were still very low at < 0.2 % Pb. Similarly, for a SOIC joint containing ~ 11 % Pb, three portable systems indicated non-compliance but gave recorded lead levels at least 10 x lower than the actual value. Thus, for identifying samples containing high lead levels (40 + %), the majority of the handheld systems are adequate, but the systems tested could not be relied upon to identify non-compliant joints where lead levels were below 3 %. Such systems may be suitable for analysing joints if sufficient joints were removed from the assembly and collected together to fill the measurement window.

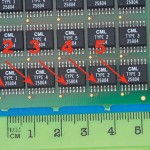

Screening SOIC joints with smaller spot sizes: The bench top Si-PIN/SiLi detector based systems, with their generally smaller spot sizes (0.1 to 2 mm diameter), were able to identify non-compliant joints, with all eight systems tested giving correct identifications.

Screening resistor joints: Spot size also played a part in the analysis of R 1206 solder joints. The latter are 3 x 2 mm, filling around 85 % of the typical measurement window of a portable system. Although no lead (< 0.1 %) was present in one sample, six systems recorded lead at levels of 0.1 to 0.8 % in the sample that was RoHS non-compliant. The majority of these systems had larger spot sizes and consequently the measurement window extended beyond the joint area and included part of the component and PCB base as shown in figure 4. The lead signal therefore included some contribution from the resistor, which was known to contain lead in the passivation layer of the resistive element. Thus incorrect RoHS non-compliances were generated.

Screening BGA joints: Several assembled BGAs were tested to determine if the XRF systems could detect/measure the lead content of the assembled BGA balls, when measured through the top of a BGA. This approach might allow non-destructive testing of completed assemblies, as may be required on imports into the EU. Only one system, using a Co 57 X-ray source, recorded any lead signal sufficient to indicate non-compliance. However, the measured values from this system were significantly below the actual sample values (1.98 % for 40 % Pb sample, and 0.32 % for a 10 % Pb sample). Hence, if lead contamination levels were low, none of the systems could be relied upon to determine RoHS compliance.

Incorrect identifications of cadmium: Again the detection of cadmium during joint testing was difficult. Six systems gave nineteen (out of 121 measurements) false indications of RoHS non-compliance. All the recorded values were less than 0.08 %.

Solder joints and proportional counter based systems: The performance of the proportional counter based systems was variable. Only two systems provided a full set of measurements, neither of which proved adequate for identifying RoHS non-compliant joints.

… of other electronic components

Screening components/solder pastes in packaging: At goods-inwards inspection, there are distinct advantages in being able to test components/materials without removing them from their secondary packaging (tapes, reels, sticks etc.). This may avoid deterioration after opening, as in the case of solder pastes, or prevent wastage, as in the case of components in reels. Handling damage in removing components from sticks can also be avoided. When testing chip resistor components on the reel, five of the eleven XRF systems evaluated (including one proportional counter based system) did not record a sufficiently high level of lead to identify the RoHS non-compliant components. Of the remaining systems, four recorded significantly lower lead levels present than was actually the case. One proportional counter based system recorded significantly higher lead (34 %) and the remaining system (proportional counter based) did not quantify the amount of lead present. When known RoHS compliant chip resistors (lead-free terminations but with lead in the passivation of the resistive element) were tested on the reel, four out of nine systems incorrectly indicated the resistors were not RoHS compliant (up to 2.4 % Pb). Thus when RoHS compliance testing of chip resistors, removal of the components from the reel is recommended.

SOIC components in sticks or tubes were also studied. Four of the ten quantitative systems could not identify non-compliant components. All four of these systems were portable, with larger spot sizes. As discussed with the SOIC solder joints, the measurement windows of these systems were relatively large compared to the component termination size, and thus the lead signal was attenuated by surrounding materials. The other systems, with generally smaller measurement windows, did not record accurate values for the lead in the terminations with values between 1.5 and 21 % for a termination with 36 % lead. For compliant components in tubes, four of the ten systems evaluated indicated that lead was present above 0.1 %, or recorded lead peaks in the relevant spectra, suggesting an incorrect RoHS non-compliance. Thus for RoHS compliance testing, removal of the components from the stick or tube would be required. For analysis in systems with larger measurement windows, several component terminations may be required to fill the window.

When a sample of Sn 62 (36 % Pb) solder paste in an unopened pot was tested, all ten systems evaluated indicated the paste was not RoHS compliant or contained lead peaks in the relevant spectra. But the measured values were, with one exception, well below the true value (in two cases as low as 1 %). For a paste contaminated with lead at a lower level (~ 1 %) in an unopened pot, four of the ten systems did not correctly identify the paste as non-compliant. When an unopened lead-free (0.040 % Pb) solder paste was examined three systems falsely indicated the paste was non-compliant. In view of the degree of uncertainty with these solder paste measurements, it is recommended that a sample sufficient to fill the measurement window of the test instrument, should be removed from the pot for testing.

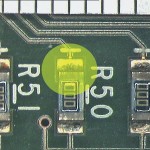

Screening chip resistors: Even when removed from their reels, the analysis of some chip resistors still presented problems. Some components with pure tin terminations were found to contain lead, the signal clearly emanating from the passivation of the resistive element. When the component was tested with the resistive element towards the detector, all twelve systems evaluated, falsely indicated the component was RoHS non-compliant, or recorded lead peaks in the spectra. The lead values varied between 0.14 and 30 %. The higher levels of lead were generally associated with those systems that used a larger measurement area. Two systems also falsely indicated that the terminations contained non-compliant levels of cadmium. Generally, it is recommended that when testing chip resistor component terminations for RoHS compliance, the resistor should be examined from the reverse side with the resistive element facing away from the instrument detector.

Care must also be exercised when testing components with multiple layers. A spacer tested during the project was RoHS compliant because its surface comprised tin-plating on brass containing lead at < 4 % (brass has an exemption in the legislation). However, when evaluated twelve of fourteen systems indicated the component was non-compliant or recorded lead peaks in the spectra. This sample illustrates that operators need a sound understanding of the materials involved in the samples in order to ensure sensible analyses. Challenging samples may require destructive testing by removing the coating and then testing separately.

Finally, a chromium-passivated zinc-coated screw was tested. Chemical tests proved inconclusive for Cr VI but chromium was clearly present on the surface. The quantitative test instruments recorded levels of chromium varying from 0.77 to 1.8 %. Clearly these XRF systems can detect the presence of chromium, but due to lack of speciation, are unable to confirm RoHS compliance. The three proportional counter systems failed to detect any chromium.

Conclusion

In conclusion, XRF systems offer a viable method of screening for RoHS compliance. Compared to chemical analysis, these systems offer lower unit cost, lower running costs and faster results. Smaller sample sizes are also possible. The use of these systems, however, does require a semiskilled operator, who has a sound understanding of the technique/equipment capabilities and the likely composition of materials involved in component assembly. Non-destructive testing is the norm but some samples may need separation into constituent parts, or removal from placement packaging, for meaningful testing.

EPP Europe 454

Acknowledgements

The NPL would like to thank the following project partners, without whose help the project would not have been possible: Alcatel Alenia Space Italia, EADS Astrium, Fischer Instrumentation (GB) Ltd., MBDA (UK) Ltd, Oxford Instruments Analytical, Research in Motion, RMD Instruments, Roentgenanalytik, Rolls Royce Marine, RS Components Ltd, Thermo Fisher Scientific Niton Analysers, Tin Technology. The work was carried out as part of a project in the Materials Processing Metrology Programme of the UK Department for Innovation, Universities and Skills.

Zusammenfassung

Das Ziel dieser Studie war es, zu beurteilen, inwieweit Röntgen-Fluoreszenz (XRF)-Systeme zur Prüfung elektronischer Teile (z. B. typische Bauteile und Baugruppen) auf das Vorhandensein gefährlicher Substanzen entsprechend der europäischen RoHS-Verordung geeignet sind. Es wurden insgesamt 15 XRF-Systeme evaluiert.

L’objectif de cette étude était de déterminer dans quelle mesure les systèmes de fluorescence aux rayons X (XRF) conviennent pour contrôler l’absence de substances dangereuses dans les composants électroniques (par ex. composants et blocs de composants typiques) conformément à la directive européenne RoHS (restriction de l’utilisation des substances dangereuses pour l’environnement). 15 systèmes XRF ont été évalués.

L’obbiettivo dello studio è valutare in che misura i sistemi a fluorescenza a raggi X (XRF) sono adatti ad accertare la presenza di sostanze pericolose nei componenti elettronici (ad es. dei componenti più comuni e dei gruppi costruttivi) in base alla normativa europea RoHS. Sono stati valutati in totale 15 sistemi XRF.

Share: