VJ Electronix has announced that it will showcase Vertex Series-A X-ray inspection system in representative Anglo Production Processes Ltd. (APP)’s booths C20 and B11 at Nepcon UK in Birmingham.

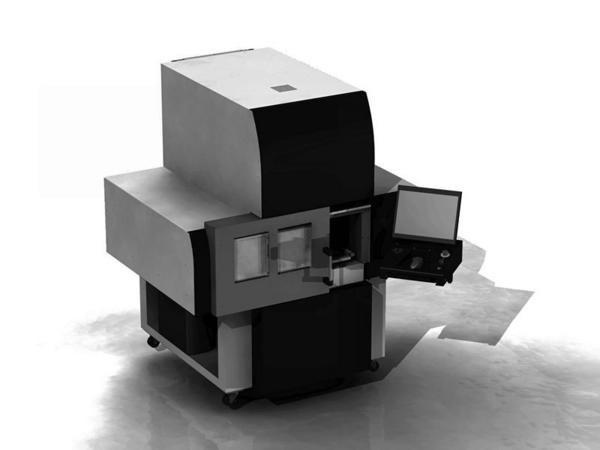

To meet significant industry challenges, the X-ray inspection system offers numerous features to help customers to inspect PCB and component assemblies quickly and accurately. A new flexible design allows it to be customized to any Inspection Task. The System allows for faster load/unload product exchange; reproducible results based on repeatability of closed-loop control system.

The Vertex Series-A offers an inspectable area of 508 x 610 mm (20 x 24”) with 100 % coverage. The large board-handling table and large inspection area are especially important to suit server boards and other large assemblies. Its modular configuration allows customers to select multiple choices of tube, detector and motion components as well as software options to optimize the system for any application. Automation of the system allows one operator to run multiple machines. Also, the large sample tray means multiple small to medium sized assemblies can be loaded at the same time.

The X-ray system is production-ready. Because it is designed for the production floor, its small footprint allows X-ray capabilities to be used in a space no greater than a conventional AOI machine. For product traceability it provides ports to accept barcode readers. It utilizes a variety of smart tubes, which sense what kind of start-up procedure is needed for minimum operator interaction in any condition.

The ergonomic design of the X-ray inspection system offers an adjustable operator console, sliding door, large window and easy sample loading. With the table moved next to the door, heavier assemblies may be loaded into the machine with minimal physical effort. Additionally, the system is easy to use because it provides on-board navigation using a camera to map inspection locations, a simplified GUI that allows easy setting or changing of X-ray parameters, local language support, 1 to 2 GO (place sample-select program-GO), automated stored inspection sequences, and export of inspection data to other systems. The use of sealed X-Ray tubes minimizes the maintenance efforts and the whole system is designed to be maintenance and service friendly.

Nepcon UK, C20 and B11

EPP Europe 460

Share: